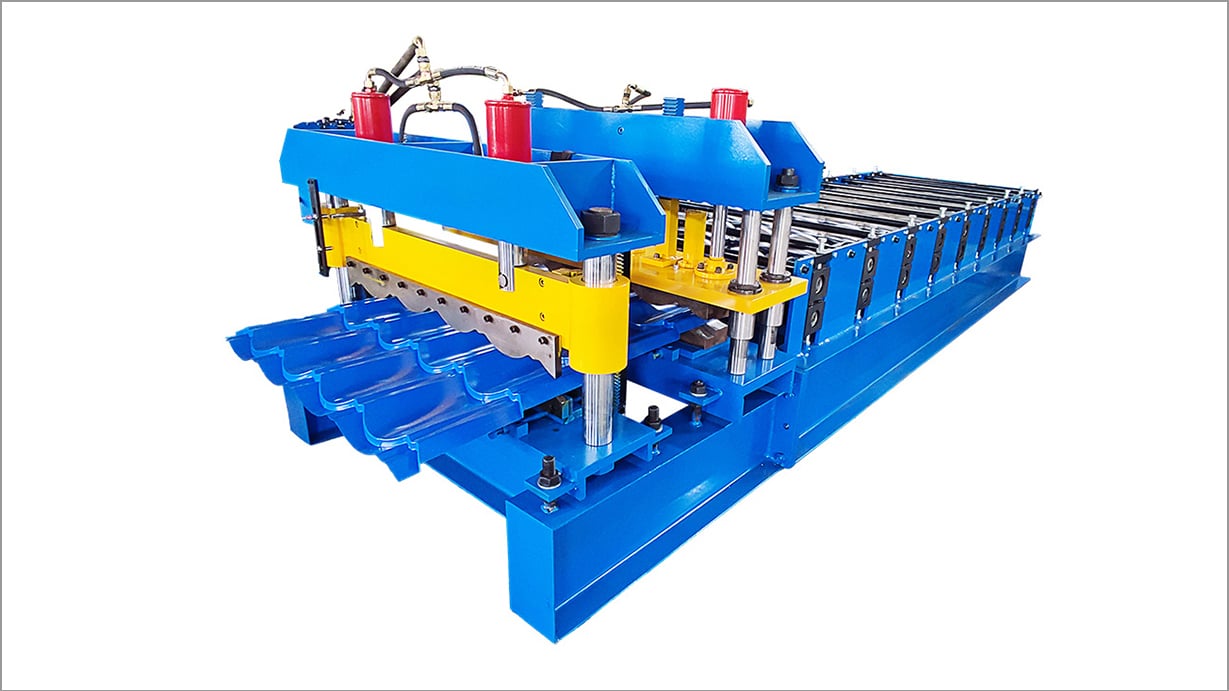

Introduction to china glazed tile roll forming machine

A China glazed tile roll forming machine is a versatile piece of equipment used in the manufacturing industry to produce high-quality glazed tiles. This machine plays a crucial role in the production process by transforming raw materials into finished products efficiently and accurately. In this article, we will explore the various aspects of China glazed tile roll forming machines, including their features, benefits, applications, and more. So, let's dive in!

The Working Principle of China Glazed Tile Roll Forming Machine

China glazed tile roll forming machines operate based on a simple yet effective working principle. The machine takes in raw materials, such as galvanized steel coils or aluminum coils, and feeds them through a series of rollers. These rollers shape the material into the desired profile, ensuring precision and uniformity. The formed tiles are then cut to the required length and can undergo additional processes, such as glazing or coating, to enhance their appearance and durability.

Features of China Glazed Tile Roll Forming Machine

China glazed tile roll forming machines are designed with several notable features that make them highly efficient and reliable. Some of the key features of these machines include:

- High Precision: The machines are equipped with advanced technology and precision-engineered components, ensuring accurate and consistent tile production.

- Customization: China glazed tile roll forming machines can be easily adjusted and customized to produce tiles of various sizes, shapes, and designs, meeting the specific requirements of different projects.

- Easy Operation: These machines are user-friendly and require minimal training to operate. They often come with intuitive control panels and automated functions, reducing human error and increasing productivity.

- Durability: Built with high-quality materials and robust construction, China glazed tile roll forming machines are designed to withstand the rigors of continuous production, ensuring long-lasting performance.

- Cost-effectiveness: By streamlining the production process and minimizing material waste, these machines help manufacturers reduce overall production costs and increase profitability.

Applications of China Glazed Tile Roll Forming Machine

China glazed tile roll forming machines find extensive applications in various industries, including:

- Construction: Glazed tiles produced by these machines are widely used in the construction industry for roofing, interior decoration, and wall cladding purposes. The tiles offer excellent weather resistance, durability, and aesthetic appeal.

- Home Improvement: China glazed tile roll forming machines cater to the needs of homeowners who desire attractive and long-lasting roofing solutions. These machines enable the production of tiles with different colors, textures, and patterns to suit any architectural style.

- Industrial Facilities: The industrial sector utilizes glazed tiles for various applications, such as warehouses, factories, and commercial buildings. The tiles provide a protective layer against harsh environmental conditions and enhance the overall appearance of the facility.

The Benefits of Using China Glazed Tile Roll Forming Machine

Utilizing a China glazed tile roll forming machine offers numerous benefits, including:

- Increased Efficiency: These machines automate the production process, significantly increasing production speed and efficiency. They can produce a large number of tiles in a relatively short period, meeting tight project deadlines.

- Improved Quality: With precise control over the forming process, China glazed tile roll forming machines ensure consistent quality across all produced tiles. This results in higher customer satisfaction and reduced rework.

- Enhanced Design Flexibility: Manufacturers can easily adjust the machine settings to create tiles of various shapes, sizes, and designs. This flexibility allows for customization and meets the diverse demands of customers.

- Reduced Labor Costs: By automating the production process, these machines require fewer manual operators, reducing labor costs and minimizing the risk of human errors.

Maintenance and Care for China Glazed Tile Roll Forming Machine

To ensure optimal performance and longevity of a China glazed tile roll forming machine, regular maintenance is essential. Some key maintenance tips include:

- Cleaning: Regularly clean the machine to remove any dust, debris, or excess material buildup that may affect its performance.

- Lubrication: Apply lubricants to the moving parts of the machine to minimize friction and ensure smooth operation.

- Inspection: Regularly inspect the machine for any signs of wear, damage, or loose connections. Address any issues promptly to avoid further damage.

- Training: Provide proper training to machine operators to ensure they understand how to operate and maintain the machine correctly.

Conclusion

A China glazed tile roll forming machine is a valuable asset for manufacturers in the tile production industry. With its advanced features, versatility, and efficiency, this machine empowers businesses to meet the growing demand for high-quality glazed tiles. By investing in a reliable China glazed tile roll forming machine and following proper maintenance practices, manufacturers can enhance their productivity, improve product quality, and stay competitive in the market.