Corrugated Roof Sheet Roll Forming Machine: A Comprehensive Guide

A corrugated roof sheet roll forming machine is a piece of manufacturing equipment used to create roofing sheets with corrugated profiles. These sheets are commonly used for roofing applications in both residential and commercial buildings. Let's dive deeper into the functionality and advantages of the corrugated roof sheet roll forming machine.

How does it work?

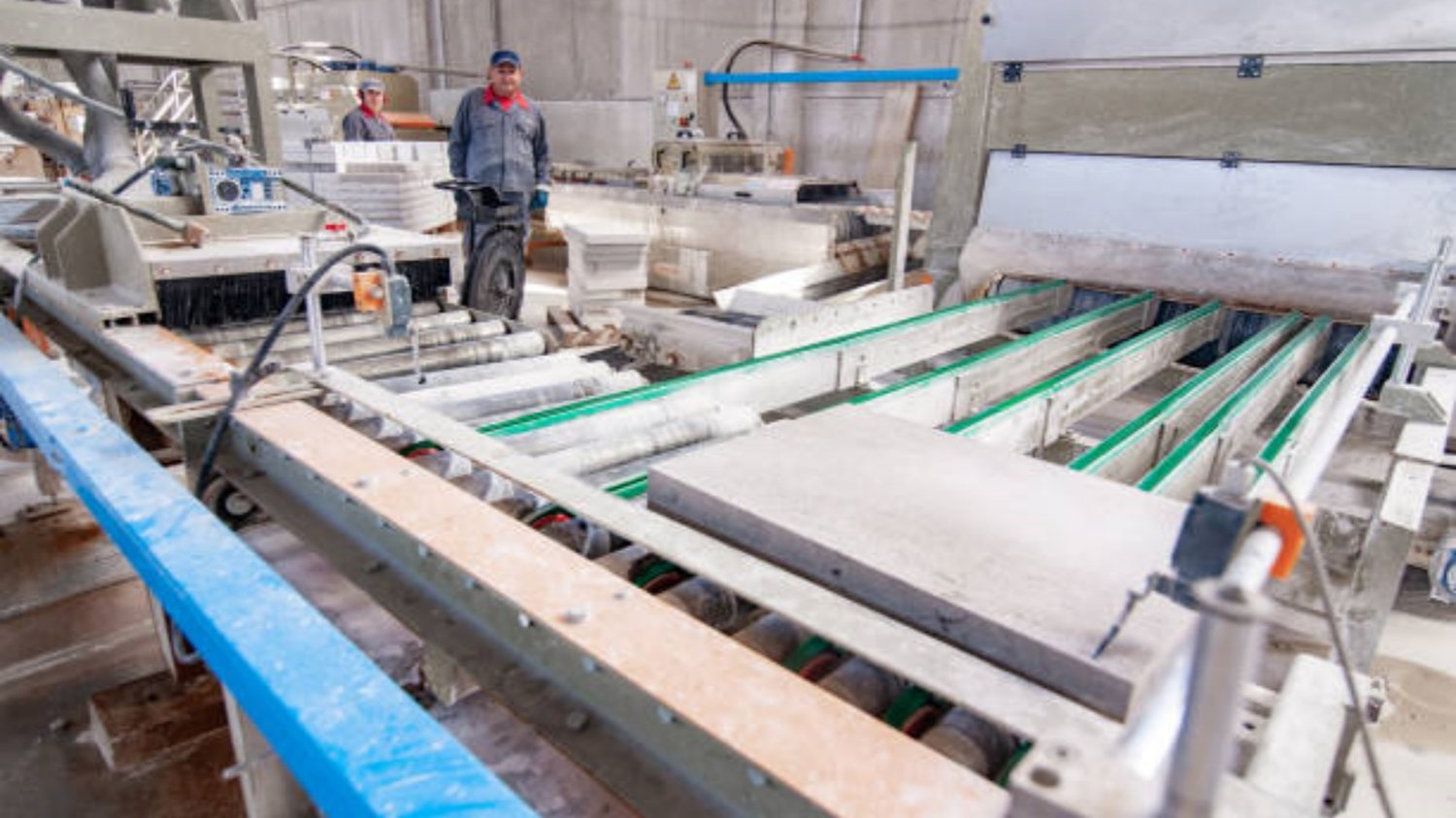

The machine generally starts by feeding large coils of metal through a series of rollers that gradually shape the material into the desired profile. The machine can be customized to produce varying profile heights, shapes, and widths. After the metal has been shaped, it can be cut to the desired length and packaged for distribution.

Advantages of Using a Corrugated Roof Sheet Roll Forming Machine

One of the biggest advantages of using a corrugated roof sheet roll forming machine is efficiency. Roofing sheets are produced quickly and accurately without the need for manual labor. The machine can operate continuously, reducing the need for frequent line stops and production downtime. Additionally, the machine produces a uniform and consistent product, which is beneficial for quality control and customer satisfaction.

Materials Used in Corrugated Roof Sheet Roll Forming

The corrugated roof sheet roll forming machine is designed to shape a wide range of materials such as steel, aluminum, copper, and other metals. Manufacturers may choose specific materials depending on various factors like cost, durability, and aesthetics. There are also galvanized options available that provide additional protection against corrosion.

Types of Corrugated Roofing Profiles

There are numerous types of corrugated roofing profiles available, each designed to meet specific needs and requirements. The most common profiles include the standard S-rib, V-rib, U-rib, and trapezoidal profiles. The S-rib profile is the most widely used and is known for its strength and durability. On the other hand, the V-rib profile is known for its superior water shedding capabilities, making it an excellent choice for areas with heavy rainfall.

Applications of Corrugated Roofing Sheets

Corrugated roofing sheets have a wide range of applications, including residential, commercial, and industrial buildings. They are also used in agriculture, particularly in greenhouses, barns, and sheds. The roofing sheets are commonly used because of their durability, versatility, and cost-effectiveness.

Maintenance of Corrugated Roofing Sheets

Maintenance of corrugated roofing sheets is critical to maximize their lifespan. While they are durable, they can still be damaged by extreme weather conditions or heavy objects falling on them. Regular inspections should be done to identify any signs of damage, including leaks or rust. Accumulated debris, such as leaves or dirt, should be removed to prevent damage to the roof surface.

Cost of Corrugated Roof Sheet Roll Forming Machine

The cost of a corrugated roof sheet roll forming machine varies depending on various factors such as machine specification, customization options, and supplier. It's important to consider factors like efficiency, productivity, and durability when choosing a machine. Investing in a high-quality machine may have a higher initial cost, but it can pay off significantly in the long run in terms of productivity and efficiency.

Future of Corrugated Roofing Sheets

The use of corrugated roofing sheets is expected to continue to grow in the future, particularly in developing countries where rural housing is in high demand. The demand for sustainable and durable roofing solutions is on the rise, and advancements in technology are making it easier and more efficient to produce high-quality roofing sheets. As such, corrugated roof sheet roll forming machines have a crucial role in shaping roofing systems in the future.

Choosing the Right Corrugated Roof Sheet Roll Forming Machine Supplier

Choosing the right supplier is critical when investing in a corrugated roof sheet roll forming machine. It's essential to select a supplier with a good reputation for quality, reliability, and customer support. It's also important to ensure the supplier can provide adequate training and maintenance support to ensure the longevity and efficiency of the machine.

Summary

Overall, a corrugated roof sheet roll forming machine is an essential piece of equipment for the production of roofing systems. It provides a cost-effective, durable, and efficient solution for roofing applications in various industries. With the increasing demand for sustainable and durable roofing solutions, the future looks bright for corrugated roofing sheets.