The Advantages of Investing in discount steel coil laser cutting machines

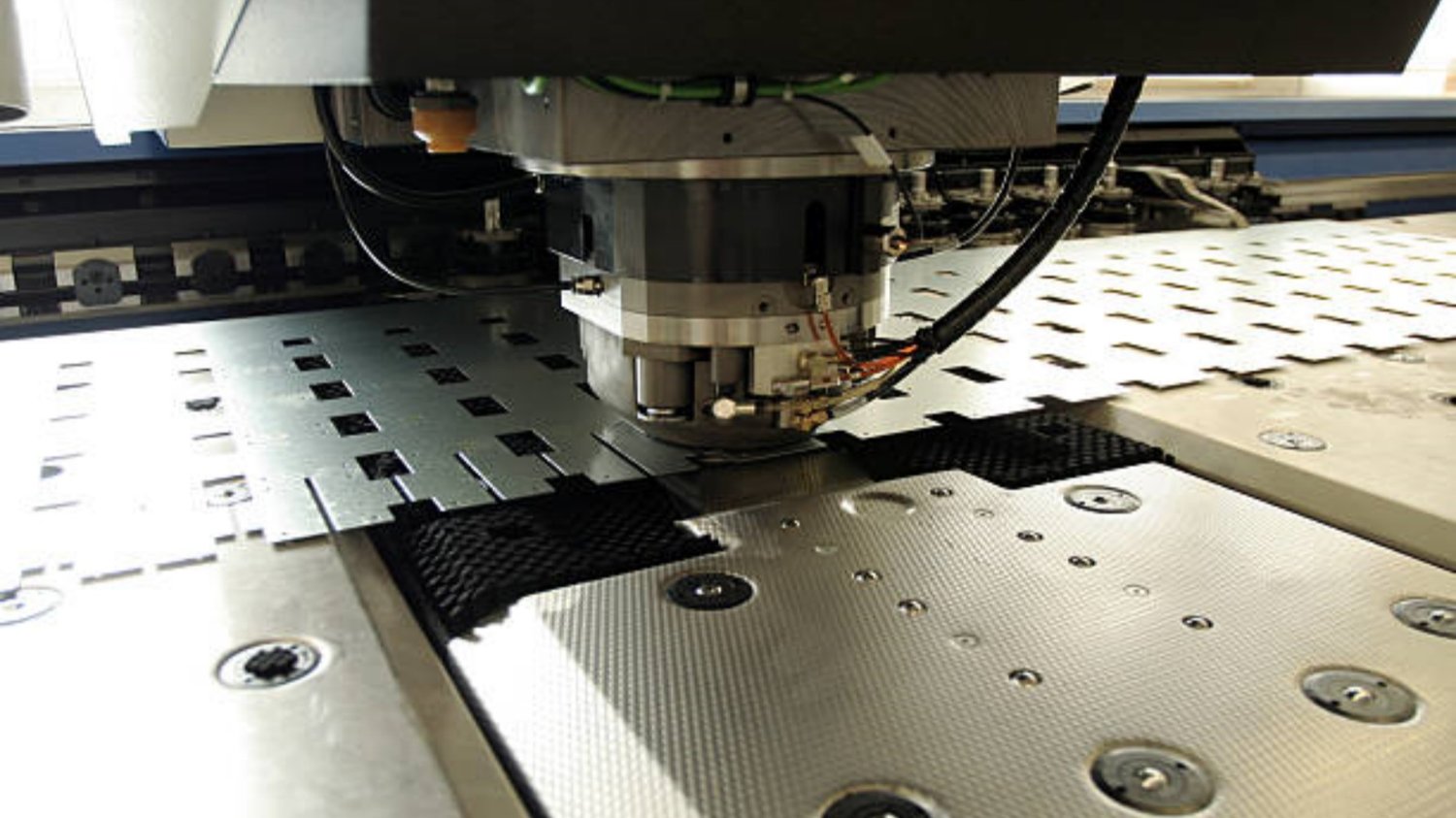

With technological advancements constantly shaping modern manufacturing industries, companies are constantly looking for efficient and cost-effective ways to improve their production processes. One of the modern tools that have revolutionized metalworking is the steel coil laser cutting machine. These machines are computer-numerically-controlled (CNC) devices that utilize high-powered lasers to cut and shape steel into various sizes and shapes. The rise of discount steel coil laser cutting machines has made them even more accessible and affordable to businesses of all sizes.

Precision Cutting

One of the most significant benefits of using a laser cutting machine on steel coils is its precision cutting capabilities. These machines use highly focused beams of light, allowing for precise cutting tolerances that are difficult to achieve otherwise. This capability is important for challenging projects that require accurate cutting and shaping.

High-Speed Manufacturing

Discount steel coil laser cutting machines also offer high-speed manufacturing capabilities. Unlike traditional cutting methods, laser cutters can provide quick and precise cuts, helping manufacturers improve production timelines and reduce overall manufacturing costs. These machines are indispensable for companies that require high-speed production of complex metal parts.

Flexibility

Discount steel coil laser cutting machines are highly flexible and versatile tools that can be used for various applications across multiple industries. The machines can cut through a wide range of metal types and thicknesses, making them a preferred choice when compared to other cutting methods. As a result, laser cutters can deliver increased value through their wide-ranging abilities.

Less Wastage

Laser cutting technology reduces material wastage by using less energy to cut and shape steel. Unlike other cutting methods, laser cutters are more efficient and produce less scrap metal, ultimately reducing the cost of operations over time. Laser cutters trim down wastage, lower production costs, and increase manufacturing efficiency overall.

Reduced Labor Costs

Discount steel coil laser cutting machines help reduce labor costs significantly. Using traditional cutting methods demands more labor and expertise to operate, which increases labor costs. However, laser cutters are CNC devices that require minimal human intervention, reducing the need for additional operators and technical staff, and saving costs on wages, health benefits, and training.

Quality Results

Another significant advantage of using discount steel coil laser cutting machines in metalworking is the high-quality cutting results they deliver consistently. They produce cleaner, more precise cuts that lead to tighter tolerances and excellent surface finishes. The results are so consistent that the need for secondary grinding and finishing is often reduced or eliminated entirely.

Customization

The flexibility and precision of steel coil laser cutting machines allow for custom fabrication of parts and products. With laser cutters, metalworking companies can design and manufacture unique products with high precision, enabling their customers to receive tailored solutions that meet their specific needs. This increased customization ability results in better quality products and increased customer satisfaction.

Cost-Effective Production

Discount steel coil laser cutting machines provide a cost-effective solution for creating products through service centers, workshops, and custom fabrication facilities. By cutting down on wastage, reducing labor costs, and increasing production speed, manufacturers can produce metal components and products at lower costs. This translates into higher profits and a competitive edge in the market.

Efficient Workflow

With the automated functionality of steel coil laser cutting machines, there is a much better process flow, resulting in better efficiency in production workflows. The lasers operate continuously and accurately, allowing for uninterrupted production runs over extended periods. As a result, companies not only benefit from low wastage rates but also reduced downtime, which enhances the overall efficiency of their workflow.

Conclusion

Discount steel coil laser cutting machines are a valuable technology for modern manufacturing. With their precision cutting, reduced labor costs, higher speeds, and superior quality results, laser cutters are key to boosting productivity, customizing products, and enhancing profits for any metalworking business.