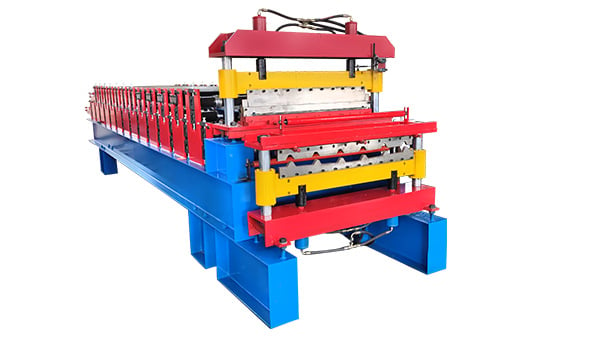

1. Introduction: Understanding the Double Layer Roll Forming Machine

The double layer roll forming machine is a highly efficient and versatile piece of equipment used in the metalworking industry. It is designed to produce two different types of profiles or sheets simultaneously, offering increased productivity and cost-effectiveness for manufacturers. In this article, we will explore the various aspects of the double layer roll forming machine, with a focus on its price and factors that affect it.

2. The Importance of Roll Forming in the Metalworking Industry

Roll forming is a popular metalworking technique that allows manufacturers to create complex and customized profiles or sheets with consistent quality. It involves feeding a metal strip through a series of roller dies, which gradually shape the material into the desired form. The double layer roll forming machine takes this process a step further by enabling the production of two different profiles simultaneously, reducing production time and costs.

3. Factors Affecting the Price of Double Layer Roll Forming Machines

The price of a double layer roll forming machine can vary significantly depending on several factors. These factors include:

- Machine Complexity: Machines with more advanced features and capabilities tend to have higher prices.

- Material Compatibility: Machines designed to work with a wide range of metals and alloys are generally more expensive.

- Production Speed: Higher production speeds usually come with a higher price tag.

- Automation Level: Fully automated machines with integrated control systems can be more costly than manual or semi-automatic machines.

4. Types of Double Layer Roll Forming Machines

There are several types of double layer roll forming machines available in the market, each catering to specific manufacturing needs. The most common types include:

- Hydraulic Double Layer Roll Forming Machine: This type of machine utilizes hydraulic power to drive the roll forming process, offering precise control and high productivity.

- Electric Double Layer Roll Forming Machine: These machines are powered by electricity and are known for their energy efficiency and ease of operation.

- Manual Double Layer Roll Forming Machine: As the name suggests, these machines require manual labor for operation and are suitable for small-scale production.

5. Advantages of Double Layer Roll Forming Machines

Investing in a double layer roll forming machine offers several advantages for manufacturers:

- Increased Productivity: The ability to produce two different profiles simultaneously significantly enhances production efficiency.

- Cost-effectiveness: By reducing production time and labor costs, double layer roll forming machines help manufacturers achieve higher profitability.

- Customizability: These machines can be easily adjusted to produce different profiles, allowing manufacturers to meet diverse customer requirements.

- Consistent Quality: Double layer roll forming machines ensure consistent product quality, reducing the chances of defects or errors.

6. Evaluating the Price-Performance Ratio

When considering the price of a double layer roll forming machine, it is vital to evaluate its performance in relation to the investment. Some key factors to consider include:

- Machine Durability: A well-built machine with robust construction and high-quality components is likely to provide better long-term performance.

- Warranty and After-Sales Support: Manufacturers offering warranty and reliable after-sales support can give you peace of mind and ensure a smooth operation of your machine.

- User Reviews and Testimonials: Checking user reviews and testimonials can provide insights into the overall performance and reliability of a particular machine.

7. Comparing Prices from Different Manufacturers

It is always recommended to compare prices from different manufacturers before making a final decision. Requesting quotes and specifications from multiple suppliers will help you get a better understanding of the market and negotiate the best possible deal. However, it is crucial to consider factors beyond price, such as the reputation of the manufacturer, product quality, and after-sales services.

8. Available Budget-Friendly Options

If you have a limited budget, there are still options available to acquire a double layer roll forming machine without compromising quality. Consider exploring the used machinery market, as well as leasing or financing options offered by manufacturers. However, ensure that the used machine is in good condition and meets your specific requirements.

9. Conclusion: Making an Informed Decision

Investing in a double layer roll forming machine can significantly enhance your manufacturing capabilities and improve your bottom line. By understanding the factors that affect the price and evaluating the price-performance ratio, you can make an informed decision that aligns with your budget and production requirements.

10. Keywords:

double layer roll forming machine price, double layer roll forming machine, roll forming machine, metalworking industry, roll forming, metal strip, hydraulic double layer roll forming machine, electric double layer roll forming machine, manual double layer roll forming machine, advantages of double layer roll forming machines, price-performance ratio, evaluating the price, comparing prices, budget-friendly options, making an informed decision