Introduction

double layer roofing sheet roll forming machines are essential equipment in the construction industry. They provide the capability to efficiently produce double-layered roofing sheets, which are commonly used in residential and commercial buildings. This article delves into the various aspects of double layer roofing sheet roll forming machines, including their benefits, working principles, and key features.

The Advantages of Using Double Layer Roofing Sheet Roll Forming Machines

Double layer roofing sheet roll forming machines offer several advantages over traditional methods of sheet manufacturing. Firstly, they significantly reduce labor costs and production time. By automating the process, these machines can produce large quantities of roofing sheets in a short period. Secondly, they ensure high precision and accuracy, resulting in uniform and consistent sheet quality. This eliminates errors and reduces waste. Thirdly, double layer roofing sheet roll forming machines are versatile and can be easily adjusted to produce different sheet profiles, meeting various design requirements.

The Working Principle of Double Layer Roofing Sheet Roll Forming Machines

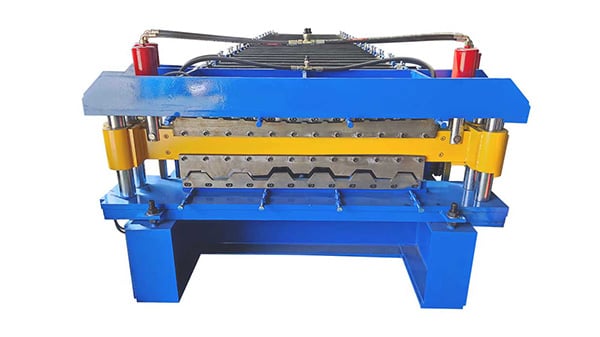

Double layer roofing sheet roll forming machines operate on a continuous process that involves feeding raw material, such as galvanized steel coils, into the machine. The material passes through a series of rollers, which gradually shape it into the desired profile. These rollers are designed to create the double-layered structure, ensuring that both layers are formed accurately. The machine also incorporates cutting mechanisms to trim the sheet to the required length. Finally, the finished roofing sheets are stacked or packaged for transportation and further processing.

Key Features of Double Layer Roofing Sheet Roll Forming Machines

Double layer roofing sheet roll forming machines are equipped with various features that enhance their performance and efficiency. One of the key features is the automatic control system, which allows operators to set precise parameters and monitor the production process. The machine also includes a hydraulic system that enables smooth and precise movement of the rollers. Additionally, many machines are equipped with a PLC (Programmable Logic Controller) system, which further enhances control and automation. Safety features, such as emergency stop buttons and protective covers, are also incorporated to ensure operator safety.

The Importance of Material Selection for Double Layer Roofing Sheet Roll Forming Machines

The choice of materials for double layer roofing sheet roll forming machines is crucial in determining the overall quality and durability of the machine. High-quality materials, such as steel alloys, are preferred for the machine's frame and components to ensure stability and longevity. The rollers, which are subjected to high stress during operation, are typically made of hardened steel to withstand wear and deformation. The selection of materials should also consider factors such as corrosion resistance and ease of maintenance.

Common Applications of Double Layer Roofing Sheet Roll Forming Machines

Double layer roofing sheet roll forming machines find wide applications in the construction industry. They are primarily used for manufacturing roofing sheets for residential, commercial, and industrial buildings. The double-layered structure provides enhanced insulation and durability, making them suitable for various climates and environments. These roofing sheets are commonly used in projects such as warehouses, factories, shopping malls, and residential complexes. Additionally, they are also utilized in the agricultural sector for constructing barns, poultry houses, and storage facilities.

Maintenance and Care for Double Layer Roofing Sheet Roll Forming Machines

Proper maintenance and care are essential to ensure the longevity and optimal performance of double layer roofing sheet roll forming machines. Regular inspections should be conducted to identify any signs of wear, damage, or misalignment. Lubrication of moving parts should be carried out as per the manufacturer's recommendations to prevent friction and ensure smooth operation. Additionally, operators should follow safety guidelines and keep the machine clean from debris and dust. Timely repairs and replacements of worn-out components are crucial to avoid production disruptions and maintain the machine's efficiency.

Choosing the Right Double Layer Roofing Sheet Roll Forming Machine

When selecting a double layer roofing sheet roll forming machine, several factors should be considered. Firstly, the machine's production capacity should align with the required output of roofing sheets. The machine's flexibility in producing different sheet profiles and sizes should also be evaluated. Additionally, the machine's reliability, durability, and after-sales support provided by the manufacturer are crucial considerations. Finally, it is essential to assess the machine's overall cost-effectiveness, taking into account factors such as energy efficiency and maintenance requirements.

Future Trends in Double Layer Roofing Sheet Roll Forming Machines

The field of double layer roofing sheet roll forming machines is continuously evolving, driven by advancements in technology and changing industry demands. Future trends in this field include the integration of artificial intelligence and machine learning algorithms to optimize production processes and minimize waste. The development of eco-friendly materials and practices will also shape the future of double layer roofing sheet roll forming machines. Additionally, the focus on energy efficiency and sustainability will drive the adoption of innovative solutions and materials to reduce environmental impact.

Conclusion

Double layer roofing sheet roll forming machines play a vital role in the construction industry, providing efficient and precise manufacturing of double-layered roofing sheets. Their numerous advantages, such as reduced labor costs, high precision, and versatility, make them indispensable in modern construction projects. By understanding the working principles, key features, and maintenance requirements of these machines, stakeholders can make informed decisions when selecting and utilizing double layer roofing sheet roll forming machines.