When it comes to efficiently producing gutters for residential and commercial buildings, gutter roll forming machines play a crucial role. These machines are designed to streamline the gutter manufacturing process and ensure precision and consistency in each gutter section produced.

What is a Gutter Roll Forming Machine?

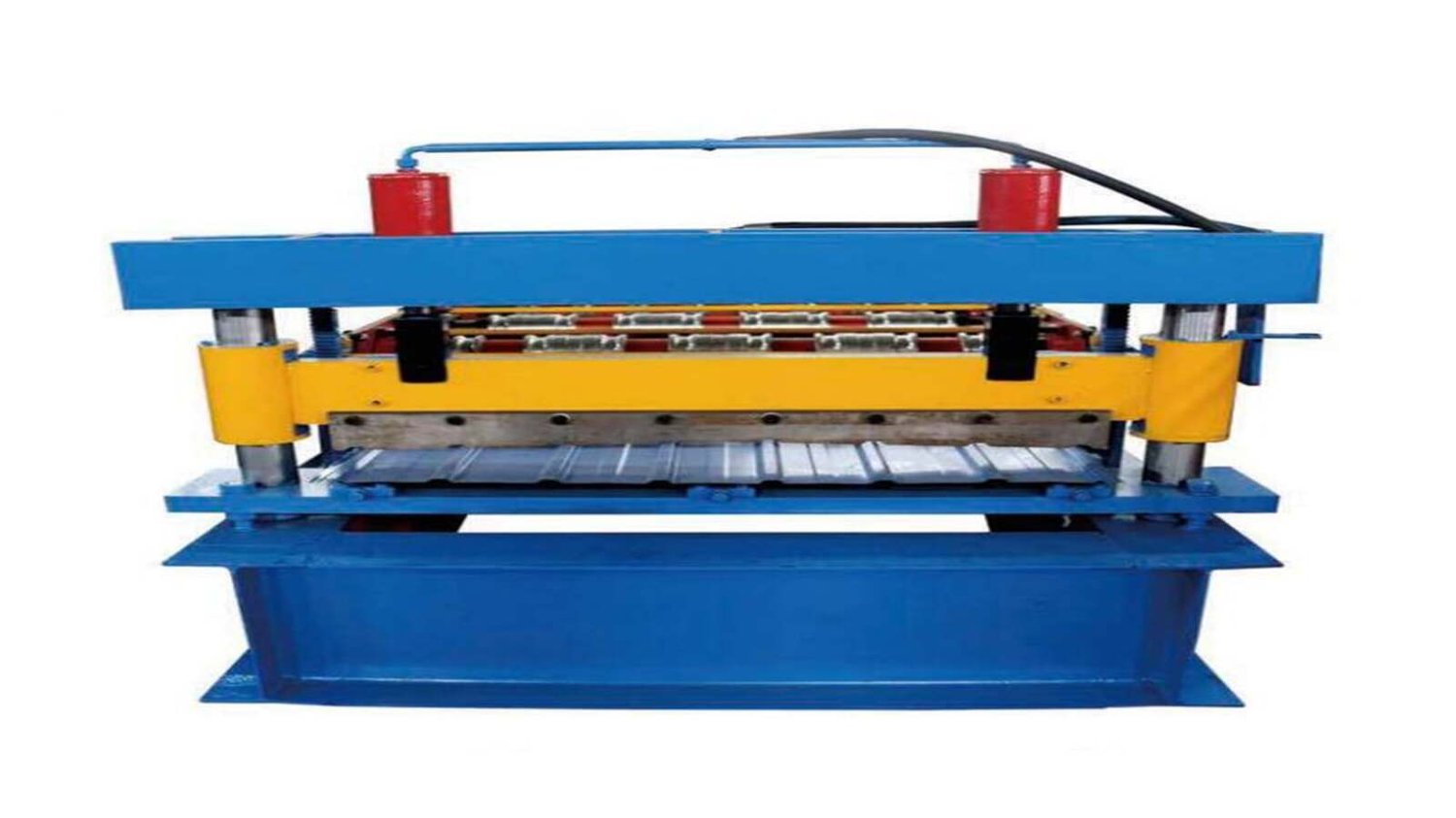

A gutter roll forming machine is a specialized piece of equipment used in the metalworking industry to fabricate continuous gutters from coils of metal. The machine uses a series of rollers to progressively shape the metal into the desired gutter profile. This automated process ensures high accuracy and speed in gutter production.

How Does a Gutter Roll Forming Machine Work?

The operation of a gutter roll forming machine involves feeding a coil of metal through the machine, where it passes through a series of rollers that gradually bend and shape the metal according to the specified gutter profile. The machine can produce gutters of various sizes and shapes, making it a versatile tool for gutter manufacturers.

Benefits of Using Gutter Roll Forming Machines

One of the key advantages of using a gutter roll forming machine is its ability to produce gutters in a continuous manner, eliminating the need for manual cutting and shaping of gutter sections. This not only increases efficiency but also reduces material waste and labor costs. Additionally, the machines can produce gutters with consistent quality and precision.

Types of Gutters Produced with Roll Forming Machines

Gutter roll forming machines can produce a wide range of gutter profiles, including K-style gutters, half-round gutters, and custom profiles to suit specific design requirements. These machines offer flexibility in gutter design and allow manufacturers to cater to various customer preferences.

Key Features to Look for in a Gutter Roll Forming Machine

When investing in a gutter roll forming machine, it is essential to consider certain features that can enhance the machine's performance and efficiency. Some key features to look for include adjustable roller stands, automatic cutting systems, and computerized controls for precise gutter production.

Applications of Gutter Roll Forming Machines

Gutter roll forming machines are widely used in the construction industry for producing gutters for residential homes, commercial buildings, and industrial facilities. These machines are essential for creating durable and weather-resistant gutters that effectively channel rainwater away from the building.

Maintenance Tips for Gutter Roll Forming Machines

Proper maintenance of gutter roll forming machines is crucial to ensure their longevity and optimal performance. Regular cleaning, lubrication of moving parts, and inspection of wear components can help prevent breakdowns and extend the machine's lifespan.

Choosing the Right Gutter Roll Forming Machine for Your Business

When selecting a gutter roll forming machine for your manufacturing business, consider factors such as production capacity, budget, and available space. It's important to choose a machine that meets your specific production needs and offers reliable performance for long-term profitability.

Future Trends in Gutter Roll Forming Technology

Advancements in roll forming technology are leading to the development of more efficient and versatile gutter roll forming machines. Features such as faster production speeds, integrated quality control systems, and enhanced automation capabilities are shaping the future of gutter manufacturing.