Introduction

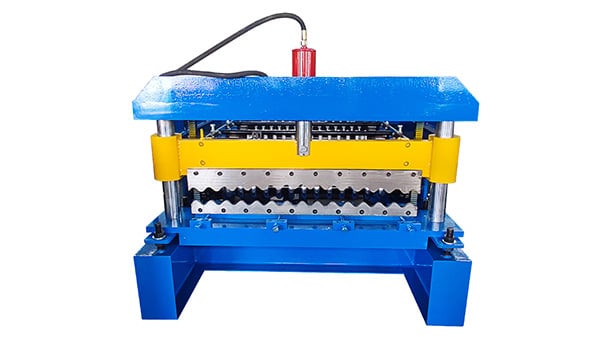

roofing corrugated sheet roll forming machines are essential tools in the construction industry. They play a crucial role in fabricating roofing sheets with corrugated designs, providing durability and strength to buildings. In this article, we will explore the various aspects of roofing corrugated sheet roll forming machines, including their functionality, benefits, types, and maintenance.

Functionality of Roofing Corrugated Sheet Roll Forming Machines

Roofing corrugated sheet roll forming machines are specifically designed to transform flat metal sheets into corrugated profiles. The machine utilizes a series of rolls and dies to bend and shape the metal sheets, creating the characteristic corrugated pattern. This process ensures uniformity and precision in the final product, resulting in high-quality roofing sheets.

The Benefits of Using Roofing Corrugated Sheet Roll Forming Machines

1. Efficiency: Roofing corrugated sheet roll forming machines automate the production process, significantly increasing efficiency compared to manual fabrication methods. They can produce a large number of roofing sheets in a short period, saving time and labor costs.

2. Customization: These machines offer the flexibility to create roofing sheets in various sizes and profiles according to specific project requirements. This customization ability ensures a perfect fit for any architectural design.

3. Durability: Roofing sheets produced by roll forming machines are highly durable and resistant to weather conditions, making them suitable for long-term use. The corrugated pattern enhances the strength and rigidity of the sheets, ensuring optimal performance even in harsh climates.

Types of Roofing Corrugated Sheet Roll Forming Machines

1. Manual Machines: These machines require operator intervention at various stages of the roll forming process. Manual machines are suitable for small-scale production or projects with specific design requirements.

2. Semi-Automatic Machines: These machines combine manual and automated processes. They require some operator input but also feature automated functions for increased efficiency.

3. Fully Automatic Machines: These machines are fully automated and can operate continuously without manual intervention. They are ideal for large-scale production and offer the highest level of efficiency.

Maintenance of Roofing Corrugated Sheet Roll Forming Machines

Maintaining roofing corrugated sheet roll forming machines is essential to ensure their longevity and optimal performance. Regular maintenance should include the following:

1. Lubrication: Proper lubrication of moving parts reduces friction and prevents wear and tear. Lubricants should be applied as per the manufacturer's guidelines.

2. Cleaning: Regular cleaning of the machine helps remove dust, debris, and metal shavings, preventing potential damage or blockages.

3. Inspection: Regular inspection of the machine's components, such as rolls, dies, and electrical systems, helps identify any signs of wear or malfunction. Prompt repairs or replacements can prevent further damage.

4. Training: Operators should receive proper training on machine operation and safety protocols to minimize the risk of accidents and ensure efficient utilization of the machine.

Conclusion

Roofing corrugated sheet roll forming machines are indispensable in the construction industry, providing a cost-effective and efficient solution for fabricating high-quality roofing sheets. These machines offer numerous benefits, such as increased productivity, customization options, and durable end products. By understanding the functionality, types, and maintenance requirements of roofing corrugated sheet roll forming machines, construction professionals can make informed decisions for their projects, leading to successful and long-lasting roofing installations.