The Importance of stainless steel coil slitting machines in the Manufacturing Industry

Stainless steel coil slitting machines play a crucial role in the manufacturing industry, particularly in metal processing and fabrication. These machines are designed to efficiently cut large coils of stainless steel into narrower strips, ensuring precision and accuracy throughout the process. In this article, we will explore the various aspects of stainless steel coil slitting machines and their significance in the industry.

Understanding the Functionality of Stainless Steel Coil Slitting Machines

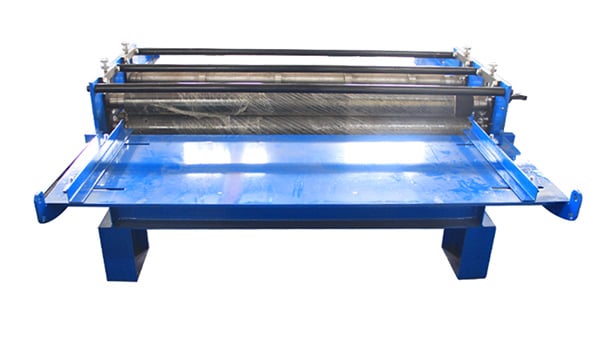

A stainless steel coil slitting machine is a specialized equipment that is specifically designed to slit stainless steel coils into smaller strips. The machine consists of several components, including a decoiler, a slitter head, tensioning devices, and a recoiler. The decoiler holds the stainless steel coil in place, while the slitter head cuts the coil into narrower strips. Tensioning devices ensure the stability of the material during the slitting process, and the recoiler collects the slit strips for further processing or packaging.

The Advantages of Stainless Steel Coil Slitting Machines

Investing in a stainless steel coil slitting machine offers numerous advantages for manufacturers. Firstly, these machines enable high precision slitting, ensuring that the strips are cut to the desired width with minimal tolerances. This level of precision is crucial in industries where accuracy is paramount. Secondly, stainless steel coil slitting machines allow for increased productivity and efficiency. The automation and speed of these machines enable manufacturers to process large volumes of stainless steel coils in a shorter time frame, leading to higher output and reduced production costs.

The Types of Stainless Steel Coil Slitting Machines

There are several types of stainless steel coil slitting machines available in the market, each catering to different needs and requirements. The most common types include manual slitting machines, semi-automatic slitting machines, and fully automatic slitting machines. Manual slitting machines require operators to manually feed and adjust the material, making them suitable for smaller-scale operations. Semi-automatic machines offer a combination of manual and automated functions, while fully automatic machines are capable of performing the entire slitting process without human intervention.

Factors to Consider When Choosing a Stainless Steel Coil Slitting Machine

When selecting a stainless steel coil slitting machine, several factors need to be taken into consideration. These include the maximum coil width and thickness that the machine can handle, the slitting speed, the accuracy of the slitting process, and the overall durability and reliability of the machine. Additionally, it is essential to consider the specific requirements of the manufacturing operation, such as the desired strip width and the volume of stainless steel coils to be processed.

The Maintenance and Care of Stainless Steel Coil Slitting Machines

Proper maintenance and care are crucial for the optimal performance and longevity of stainless steel coil slitting machines. Regular cleaning and lubrication of the machine's components, such as the slitter head and tensioning devices, help prevent friction and ensure smooth operation. It is also important to inspect and replace any worn-out parts to avoid potential breakdowns or damage to the stainless steel coils. Additionally, operators should follow the manufacturer's guidelines for safe operation and conduct routine inspections for any signs of wear or malfunction.

The Role of Stainless Steel Coil Slitting Machines in Various Industries

Stainless steel coil slitting machines find applications in a wide range of industries that utilize stainless steel strips. These industries include automotive, construction, electronics, appliances, and manufacturing. In the automotive industry, for example, stainless steel strips are used for various components such as exhaust systems, trim, and decorative elements. In the construction industry, stainless steel strips are utilized for roofing, cladding, and structural elements. The versatility of stainless steel coil slitting machines makes them indispensable in meeting the diverse needs of these industries.

The Future of Stainless Steel Coil Slitting Machines

As technology continues to evolve, stainless steel coil slitting machines are likely to undergo further advancements and improvements. These machines are expected to become more automated and integrated with other manufacturing processes, leading to increased efficiency and productivity. Additionally, advancements in materials and cutting techniques may result in even higher precision and faster slitting speeds. With the growing demand for stainless steel products across various industries, the future of stainless steel coil slitting machines looks promising.

Conclusion

Stainless steel coil slitting machines are essential tools in the manufacturing industry, enabling precise and efficient cutting of stainless steel coils into narrower strips. The advantages of these machines, such as high precision, increased productivity, and versatility, make them indispensable for industries that rely on stainless steel strips. By understanding the functionality, types, and maintenance of stainless steel coil slitting machines, manufacturers can make informed decisions and optimize their production processes.