The Ultimate Guide to glazed tile roll forming machine manufacturers

Introduction:

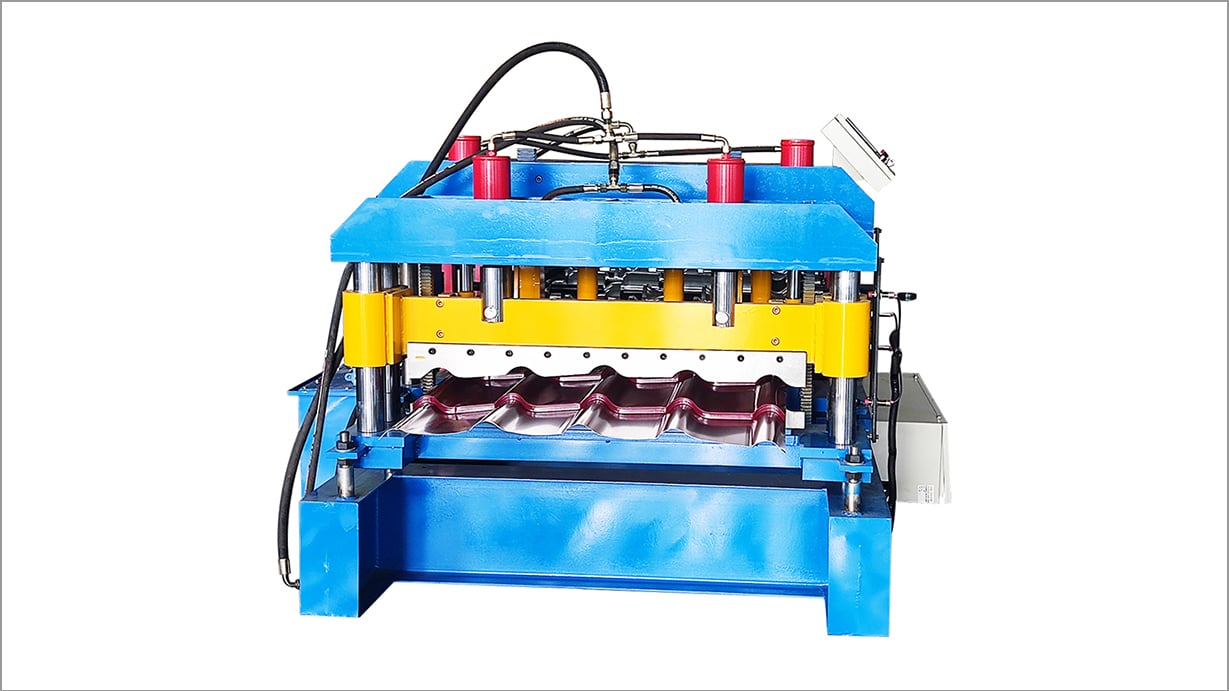

Glazed tile roll forming machines have revolutionized the production of high-quality glazed tiles in the construction industry. These machines are designed to efficiently and accurately produce glazed tiles of various shapes and sizes, meeting the demands of modern architecture. In this comprehensive guide, we will explore the world of glazed tile roll forming machine manufacturers, discussing their importance, key features, benefits, and the top manufacturers in the market.

1. Understanding Glazed Tile Roll Forming Machines

Glazed tile roll forming machines are specialized equipment used in the manufacturing process of glazed tiles. These machines employ a continuous process that transforms raw materials, such as steel coils, into finished glazed tiles. The process involves feeding the raw material through a series of rollers and presses, which shape and form the tiles. The result is a consistent and high-quality product that meets the specifications of the construction industry.

2. Key Features of Glazed Tile Roll Forming Machines

Glazed tile roll forming machines come with several key features that make them essential in the production of glazed tiles:

- Precision: These machines are designed to deliver precise and accurate results, ensuring that each glazed tile meets the required specifications.

- Automation: With advanced automation technology, these machines can operate continuously, reducing human error and increasing productivity.

- Customization: Glazed tile roll forming machines can be easily adjusted to produce tiles of different shapes, sizes, and designs, allowing for flexibility in production.

- Efficiency: These machines are highly efficient, with fast production cycles and minimal waste, making them cost-effective for manufacturers.

3. Benefits of Using Glazed Tile Roll Forming Machines

Utilizing glazed tile roll forming machines in the manufacturing process offers several benefits to manufacturers:

- High-Quality Output: These machines ensure consistent and high-quality glazed tiles, meeting the standards and expectations of the construction industry.

- Increased Productivity: With automated processes, these machines can produce glazed tiles at a faster rate, improving overall productivity and reducing labor costs.

- Cost-Effective: Glazed tile roll forming machines minimize material waste and optimize production efficiency, resulting in cost savings for manufacturers.

- Flexibility: Manufacturers can easily customize the machines to produce glazed tiles of different shapes, sizes, and designs, catering to diverse customer demands.

4. Top Glazed Tile Roll Forming Machine Manufacturers

When considering glazed tile roll forming machine manufacturers, it is crucial to choose a reputable and reliable supplier. Here are some of the top manufacturers in the market:

- Manufacturer A: Known for their cutting-edge technology and superior quality machines, Manufacturer A has established a strong reputation in the industry.

- Manufacturer B: With a focus on innovation and customer satisfaction, Manufacturer B offers a wide range of glazed tile roll forming machines to meet various production needs.

- Manufacturer C: Renowned for their efficient and durable machines, Manufacturer C has a proven track record of delivering reliable glazed tile roll forming equipment.

5. Factors to Consider When Choosing a Glazed Tile Roll Forming Machine Manufacturer

Before making a decision, it is important to consider several factors when choosing a glazed tile roll forming machine manufacturer:

- Quality: Ensure that the manufacturer has a reputation for producing high-quality machines that meet industry standards.

- Experience: Look for manufacturers with years of experience in the industry, as this indicates their expertise and knowledge in producing reliable machines.

- Customer Support: Check if the manufacturer provides comprehensive customer support, including installation, training, and after-sales service.

- Price: Compare prices from different manufacturers, considering the overall value provided by the machine rather than solely focusing on the initial cost.

6. Maintenance and Care for Glazed Tile Roll Forming Machines

Proper maintenance and care are essential to ensure the longevity and optimal performance of glazed tile roll forming machines. Here are some key maintenance tips:

- Regular Cleaning: Clean the machine regularly to remove any debris or dust that may affect its performance.

- Lubrication: Apply lubricants to the moving parts of the machine to reduce friction and prevent wear and tear.

- Inspection: Regularly inspect the machine for any signs of damage or wear, and address any issues promptly to prevent further damage.

- Training: Provide proper training to operators on machine operation and maintenance to ensure safe and efficient usage.

7. The Future of Glazed Tile Roll Forming Machine Manufacturers

The future of glazed tile roll forming machine manufacturers looks promising. With advancements in technology, these machines will become more efficient, precise, and customizable. Manufacturers will continue to prioritize sustainability and environmental friendliness in their production processes, further reducing waste and energy consumption.

8. Conclusion

Glazed tile roll forming machines play a crucial role in the production of high-quality glazed tiles. Understanding their features, benefits, and factors to consider when choosing a manufacturer is essential for manufacturers in the construction industry. By selecting a reputable and reliable manufacturer, businesses can enhance their productivity, reduce costs, and deliver superior glazed tiles to meet market demands.