How does a roll forming machine work??

Roll forming machines are widely used in various industries for shaping and forming metal sheets into desired profiles. This article provides a comprehensive guide on how these machines work, including the key components and the step-by-step process involved. Whether you are a curious individual or a professional in the field, this article will help you understand the inner workings of a roll forming machine.

The Basics: Introduction to Roll Forming Machines

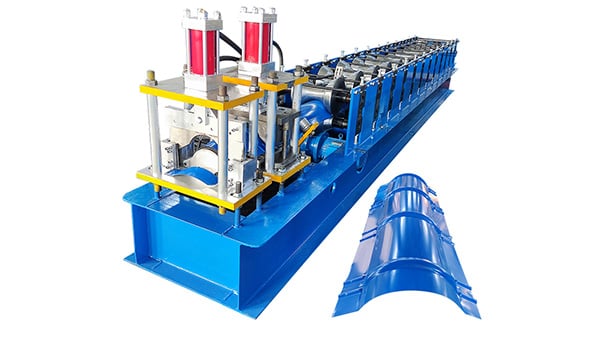

Roll forming machines are specialized equipment designed to automate the process of shaping and forming metal sheets, typically made of steel or aluminum, into specific profiles. These machines use a continuous bending operation in which a long strip of metal passes through multiple sets of rolls, gradually forming the desired shape.

Roll forming is commonly used in industries such as construction, automotive, and manufacturing, where the demand for consistent and precise metal profiles is high. Let's delve deeper into the key components and the step-by-step process of a roll forming machine.

Key Components of a Roll Forming Machine

A roll forming machine consists of several crucial components that work together to ensure the smooth and efficient operation of the machine. Here are the key components of a typical roll forming machine:

1. Uncoiler

The uncoiler is the first component of a roll forming machine. It holds the metal coil and feeds it into the machine for further processing. The uncoiler usually has a brake system to control the tension of the metal strip, ensuring a consistent feed into the machine.

2. Leveler

The leveler straightens the metal strip as it enters the roll forming machine. It removes any imperfections or bends, ensuring a flat and even surface for proper forming.

3. Rollers

The heart of a roll forming machine lies in its rollers. These are sets of specially designed rolls that gradually shape the metal strip into the desired profile. Each set of rollers performs a specific bending operation, gradually forming the metal strip step by step.

4. Cut-off Tool

Once the metal strip has been fully formed, the cut-off tool is used to cut it into the desired length. This tool can be either a shear or a flying cutoff, depending on the specific requirements of the application.

5. Control System

The control system of a roll forming machine is responsible for managing and monitoring the entire process. It controls the speed of the machine, adjusts the settings, and ensures the proper synchronization of all components. Modern roll forming machines often have advanced computerized control systems for enhanced precision and efficiency.

The Step-by-Step Process of a Roll Forming Machine

Now that we understand the key components of a roll forming machine, let's explore the step-by-step process involved:

Step 1: Coil Loading

The metal coil is loaded onto the uncoiler, which holds it securely in place. The uncoiler feeds the metal strip into the roll forming machine, ensuring a continuous supply of material.

Step 2: Leveling

The metal strip passes through the leveler, which removes any imperfections and straightens it to ensure a flat and even surface. This step is essential for achieving precise and consistent results.

Step 3: Roll Forming

The metal strip enters the series of rollers, which gradually shape it into the desired profile. Each set of rollers performs a specific bending operation, incrementally forming the metal strip. The speed and pressure of the rollers are carefully controlled to ensure accurate shaping.

Step 4: Cut-off

Once the metal strip has been fully formed, the cut-off tool is activated to cut it into the desired length. The cut-off tool can be either a shear, which cuts the metal strip while it is stationary, or a flying cutoff, which cuts the strip while it is in motion.

Step 5: Stacking or Packaging

After the cut-off process, the formed metal profiles are either stacked or packaged according to the specific requirements. This ensures easy handling and transportation of the finished products.

Conclusion

Roll forming machines play a crucial role in shaping and forming metal sheets into various profiles. Understanding how these machines work is essential for anyone involved in metal fabrication or interested in the manufacturing process. From the key components to the step-by-step process, we have covered the fundamental aspects of a roll forming machine. With their ability to produce consistent and precise metal profiles, roll forming machines continue to be a valuable asset in various industries.