Introduction

Are you in the market for a roofing sheet roll forming machine? Do you want to know the price range and factors that influence it? Look no further! In this article, we will delve into the world of roofing sheet roll forming machines and explore their prices, features, and more. Whether you are a roofing contractor or a business owner looking to invest in one, this comprehensive guide will provide you with all the information you need to make an informed decision.

The Importance of a Roofing Sheet Roll Forming Machine

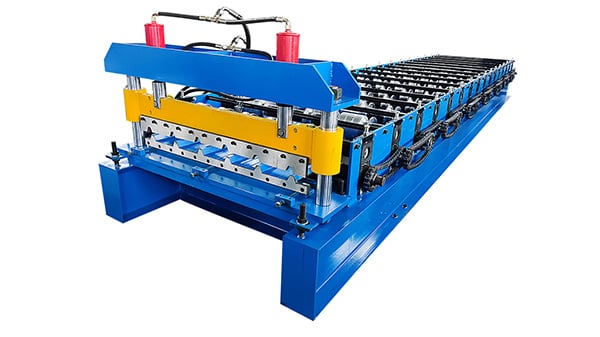

A roofing sheet roll forming machine is an essential piece of equipment for any roofing project. It is used to transform flat metal sheets into various roofing profiles, such as corrugated sheets, standing seam panels, and more. This machine saves time and effort by automating the process of forming metal sheets, resulting in precise and uniform products. With the right machine, you can produce high-quality roofing sheets that meet the specific requirements of your clients.

Factors Affecting roofing sheet roll forming machine prices

1. Machine Capacity: The size and capacity of the machine play a significant role in determining its price. Machines with higher production capacities and larger roll forming stations are generally more expensive.

2. Material Thickness: The maximum thickness of the metal sheet that the machine can handle affects its price. Machines capable of processing thicker materials tend to be pricier.

3. Material Type: Different machines are designed to handle specific types of materials, such as steel, aluminum, or copper. Machines capable of processing a wider range of materials usually come with a higher price tag.

4. Customization Options: Some machines offer customization options, allowing you to create unique roofing profiles. These machines tend to be more expensive than standard models.

5. Automation Level: Machines with higher levels of automation, such as computer numerical control (CNC) systems, tend to be more expensive. However, they offer increased precision and efficiency.

Roofing Sheet Roll Forming Machine Price Range

The price of a roofing sheet roll forming machine can vary significantly depending on its specifications and features. On average, you can expect to pay anywhere between $10,000 and $50,000 for a reliable and high-quality machine. However, sophisticated machines with advanced features can cost upwards of $100,000. It is important to carefully consider your specific needs and budget before making a purchase.

Benefits of Investing in a Roofing Sheet Roll Forming Machine

1. Cost Savings: By investing in your own roll forming machine, you can save money on outsourcing the production of roofing sheets. Over time, this can lead to significant cost savings for your business.

2. Increased Productivity: With a roll forming machine, you can produce roofing sheets at a much faster rate compared to manual methods. This increased productivity allows you to take on more projects and meet tight deadlines.

3. Quality Control: By having full control over the production process, you can ensure that the roofing sheets meet your desired quality standards. This can enhance your reputation and customer satisfaction.

4. Versatility: A roofing sheet roll forming machine offers versatility in terms of the types of roofing profiles you can create. You can easily switch between different profiles, catering to the diverse needs of your clients.

5. Long-Term Investment: Investing in a high-quality roll forming machine is a long-term investment that can provide returns for many years to come. With proper maintenance and care, these machines have a long lifespan.

Choosing the Right Roofing Sheet Roll Forming Machine

When selecting a roofing sheet roll forming machine, it is essential to consider several factors:

1. Production Capacity: Determine the volume of roofing sheets you need to produce to choose a machine with an appropriate production capacity.

2. Material Compatibility: Ensure that the machine is compatible with the type and thickness of the materials you plan to use.

3. Customization Options: If you require unique roofing profiles, opt for a machine that offers customization capabilities.

4. Automation Level: Consider the level of automation that suits your requirements and budget.

5. After-Sales Support: Look for a reputable manufacturer that offers reliable after-sales support, including maintenance services and spare parts availability.

In conclusion

Investing in a roofing sheet roll forming machine can significantly boost your roofing business's efficiency and profitability. By understanding the key factors that influence the machine's price and considering your specific needs, you can make an informed decision. Remember to choose a machine from a reputable manufacturer and prioritize quality, reliability, and after-sales support. With the right machine, you can streamline your production process, produce high-quality roofing sheets, and stay ahead of the competition.