The Importance of steel floor decking roll forming machine in Construction

1. Understanding the Steel Floor Decking Roll Forming Machine

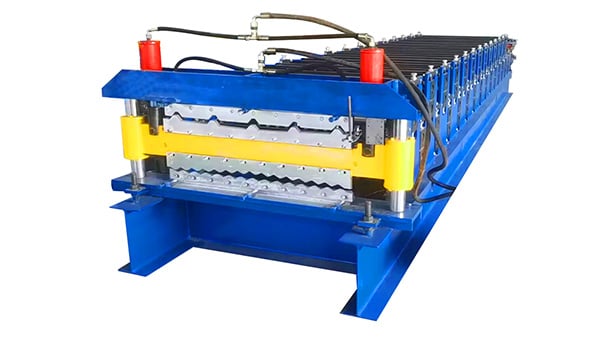

A steel floor decking roll forming machine is a vital equipment used in the construction industry to produce steel floor decking panels. These panels are commonly used in commercial and industrial buildings to provide structural support and a solid base for concrete floors and roofs. The machine is designed to take a coil of steel and transform it into a finished product with precise dimensions and shapes.

2. The Roll Forming Process

The roll forming process is the key technique employed by the steel floor decking roll forming machine. It involves passing the steel coil through a series of rollers, each designed to gradually shape the material into the desired profile. The machine's computerized control system ensures the accuracy and consistency of each panel produced.

3. Benefits of Steel Floor Decking

Steel floor decking offers numerous advantages in construction. Firstly, it provides excellent structural support, making it suitable for heavy loads and reducing the risk of deflection or collapse. Additionally, steel floor decking acts as a formwork during the concrete pouring process, saving time and labor costs. It also enhances fire resistance and improves acoustic insulation in the building.

4. Versatility in Design of steel floor decking roll forming machine

Steel floor decking roll forming machines allow for a wide range of design options. The machines can produce different profiles, such as trapezoidal or corrugated, to meet specific project requirements. The flexibility in design ensures that the steel floor decking panels can seamlessly integrate with other building components and systems.

5. High Production Efficiency

With the advancement in technology, modern steel floor decking roll forming machines offer high production efficiency. The machines can operate at high speeds, producing a large number of panels in a short amount of time. This efficiency helps to meet project deadlines and reduces overall construction costs.

6. Quality and Precision of steel floor decking roll forming machine

Steel floor decking roll forming machines are known for their exceptional quality and precision. The machines are equipped with advanced control systems, ensuring accurate dimensions, consistent shapes, and smooth finishes for every panel produced. The high-quality output of these machines contributes to the overall durability and longevity of the building.

7. Cost Savings of steel floor decking roll forming machine

Investing in a steel floor decking roll forming machine can lead to significant cost savings in the long run. By producing the steel floor decking panels on-site, construction companies can eliminate the need for outsourcing and transportation costs. Moreover, the efficiency of the machine reduces labor expenses and minimizes material waste.

8. Durability and Sustainability of steel floor decking roll forming machine

Steel floor decking panels are known for their durability and sustainability. The use of high-quality steel and the precision manufacturing process ensure that the panels can withstand various weather conditions and provide long-lasting structural support. Additionally, steel is a recyclable material, making it an environmentally friendly choice for construction projects.

9. Maintenance and Safety

Maintaining steel floor decking panels is relatively simple and cost-effective. Regular inspections and minor repairs can extend their lifespan and ensure their continued performance. Furthermore, the use of steel floor decking enhances safety on construction sites by providing a stable working platform and reducing the risk of accidents.

10. Choosing the Right Steel Floor Decking Roll Forming Machine

When selecting a steel floor decking roll forming machine, several factors should be considered. These include the desired panel profile, production capacity, machine reliability, and after-sales support. Investing in a reputable manufacturer with a proven track record can ensure the machine's quality and longevity.