Introduction

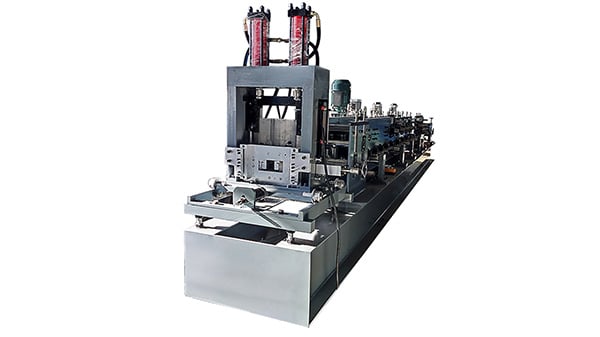

When it comes to manufacturing high-quality CZ purlins, having a reliable roll forming machine is essential. In this article, we will explore the benefits of investing in a cheap cz purlin roll forming machine. From cost savings to improved efficiency, this equipment can revolutionize your production process.

Cost Savings of a Cheap CZ Purlin Roll Forming Machine

One of the primary advantages of investing in a cheap CZ purlin roll forming machine is the significant cost savings it offers. Compared to traditional manufacturing methods, such as welding or cutting, roll forming machines provide a more affordable solution. With its efficient design and streamlined production process, this machine minimizes material waste and reduces labor costs, ultimately leading to substantial savings.

Durability and Longevity of a Cheap CZ Purlin Roll Forming Machine

A cheap CZ purlin roll forming machine does not compromise on the durability and longevity of the final product. These machines are built to withstand heavy usage and are constructed with high-quality materials. By investing in a roll forming machine, you can ensure that your CZ purlins will maintain their structural integrity for years to come, reducing the need for frequent replacements or repairs.

High Precision and Customization of a Cheap CZ Purlin Roll Forming Machine

With advancements in technology, cheap CZ purlin roll forming machines offer exceptional precision and customization options. These machines are equipped with advanced computerized controls, allowing you to achieve accurate dimensions and tight tolerances. Additionally, roll forming machines can easily be adjusted to accommodate various sizes and profiles, providing versatility in your production capabilities.

Increased Efficiency of a Cheap CZ Purlin Roll Forming Machine

Another significant advantage of investing in a cheap CZ purlin roll forming machine is the increased efficiency it brings to your manufacturing process. These machines operate at high speeds, allowing for rapid production and shorter lead times. By automating the roll forming process, you can reduce manual labor, improve workflow, and optimize overall productivity.

Consistent Quality of a Cheap CZ Purlin Roll Forming Machine

One of the challenges in manufacturing CZ purlins is maintaining consistent quality throughout the production process. Cheap CZ purlin roll forming machines address this issue by ensuring uniformity in each product. With precise control over the forming process, these machines produce purlins with consistent dimensions, surface finish, and structural integrity, meeting the highest quality standards.

Reduced Material Waste of a Cheap CZ Purlin Roll Forming Machine

Traditional manufacturing methods often result in significant material waste, leading to increased costs and environmental concerns. However, cheap CZ purlin roll forming machines minimize material waste by utilizing efficient roll forming techniques. These machines optimize the use of raw materials, reducing scrap and minimizing the overall environmental impact of your manufacturing operations.

Quick Set-Up and Easy Operation

Investing in a cheap CZ purlin roll forming machine not only improves production efficiency but also simplifies the setup and operation process. These machines are designed to be user-friendly, with intuitive controls and clear instructions. With minimal training, your operators can quickly learn how to operate the machine, reducing downtime and ensuring a smooth production workflow.

Space-Saving Design

Space is often a valuable asset in any manufacturing facility. Cheap CZ purlin roll forming machines are designed with a compact footprint, making them ideal for facilities with limited space. Their efficient design allows you to maximize the use of your floor area, providing ample room for other equipment or processes.

Improved Safety of a Cheap CZ Purlin Roll Forming Machine

Lastly, investing in a cheap CZ purlin roll forming machine promotes a safer working environment. These machines are equipped with safety features and mechanisms to prevent accidents and injuries during operation. By automating the roll forming process, you can minimize the need for manual handling of materials, reducing the risk of workplace accidents.