Introduction

When it comes to constructing buildings, one crucial aspect is the flooring system. The composite floor deck is a popular choice due to its durability and strength. To efficiently produce composite floor decks, a composite floor deck roll forming machine is necessary. This article explores the various aspects and benefits of using a composite floor deck roll forming machine in construction projects.

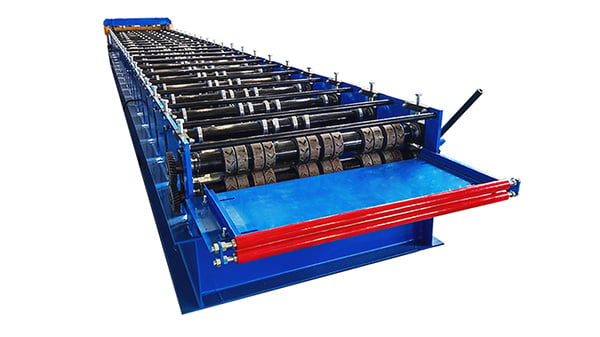

The Function of a Composite Floor Deck Roll Forming Machine

A composite floor deck roll forming machine is a specialized piece of equipment designed to fabricate composite floor decks. It is used to shape and cut metal sheets into precise profiles that are suitable for constructing composite floor decks. The machine works by feeding the metal sheets through a series of rollers, which gradually shape the material. Once the desired profile is achieved, the machine cuts the sheet to the required length, ready for installation.

Efficiency and Speed in Production

Using a composite floor deck roll forming machine significantly increases the efficiency and speed of production. Traditional methods of fabricating composite floor decks involve manual cutting and shaping of metal sheets, which is time-consuming and labor-intensive. With a roll forming machine, the process is automated, reducing the need for manual labor and increasing productivity. The machine can produce a high volume of composite floor decks in a short period, allowing construction projects to progress swiftly.

Precision and Consistency in Profile Formation

One of the key advantages of using a composite floor deck roll forming machine is the precision and consistency it offers in profile formation. The rollers in the machine are designed to create uniform shapes with accurate dimensions. This ensures that each composite floor deck produced is of the same high quality, eliminating variations and inconsistencies that could negatively impact the overall structural integrity of the building.

Flexibility in Profile Design of a Composite Floor Deck Roll Forming Machine

A composite floor deck roll forming machine provides great flexibility in profile design. The machine can be adjusted to create different profiles according to the specific requirements of the project. This adaptability allows architects and engineers to explore various design possibilities and choose the most suitable profile for their construction projects. The ability to customize profiles ensures that the composite floor decks perfectly fit the intended use and aesthetic preferences.

Cost Savings in Material and Labor of a Composite Floor Deck Roll Forming Machine

Using a composite floor deck roll forming machine can result in significant cost savings in both material and labor. The machine optimizes the use of metal sheets, minimizing wastage and reducing material expenses. Additionally, the automated process eliminates the need for extensive manual labor, reducing labor costs. These cost savings make the use of a roll forming machine a cost-effective solution for construction projects, especially for large-scale developments.

Improved Structural Performance of a Composite Floor Deck Roll Forming Machine

The precise and consistent profile formation achieved by a composite floor deck roll forming machine contributes to improved structural performance. The uniformity of the profiles ensures that the composite floor decks have the necessary strength and load-bearing capacity. This is essential for creating safe and durable flooring systems, especially in buildings where heavy loads or vibrations are anticipated. The use of a roll forming machine enhances the overall structural integrity of the building.

Enhanced Construction Site Safety of a Composite Floor Deck Roll Forming Machine

Construction site safety is of utmost importance, and using a composite floor deck roll forming machine can contribute to enhancing safety levels. The automated process reduces the need for manual handling of heavy metal sheets, minimizing the risk of injuries related to lifting and carrying materials. Additionally, the precise profile formation ensures that the composite floor decks fit together seamlessly, reducing the chances of accidents or structural failures during installation.

Time Efficiency in Construction Projects of a Composite Floor Deck Roll Forming Machine

With the increased speed of production offered by a composite floor deck roll forming machine, construction projects can be completed in a shorter time frame. The quick fabrication of composite floor decks allows for faster installation, accelerating the overall construction process. This time efficiency is particularly beneficial in projects with tight deadlines or where delays can have significant financial implications. The use of a roll forming machine helps meet project timelines and ensures timely project completion.

Durability and Longevity of Composite Floor Decks

Composite floor decks produced using a roll forming machine are known for their durability and longevity. The precise profile formation and high-quality materials used in the process result in robust composite floor decks that can withstand heavy loads and harsh environmental conditions. The long lifespan of these floor decks minimizes the need for frequent repairs or replacements, reducing maintenance costs and ensuring the longevity of the building.

Conclusion

A composite floor deck roll forming machine offers numerous benefits in the construction industry. From increased efficiency and speed of production to enhanced structural performance and site safety, the machine proves to be an invaluable asset. Its flexibility in profile design and cost-saving advantages make it a preferred choice for construction projects. With the durability and longevity of composite floor decks produced using this machine, buildings are built to last. Incorporating a composite floor deck roll forming machine in construction projects is a wise investment that yields long-term benefits.