Roller shutter doors are essential in the commercial and industrial sectors. They provide security and access control to business premises. The roller shutter door roll forming machine is the equipment used in producing these doors. It utilizes a roll forming process in molding and shaping the metal sheets into the roller shutter doors.

The Advantages of Using a Roller Shutter Door Roll Forming Machine

Roller shutter door roll forming machines offer numerous benefits. One of them is precision. The roll forming process produces accurate and consistent shapes every time. The result is high-quality roller shutter doors that meet the standards of the industry. Another advantage is speed. Roll forming machines can produce large volumes of roller shutter doors in a short amount of time. Plus, the process is automated, which means that manpower requirements are reduced.

The Components of a Roller Shutter Door Roll Forming Machine

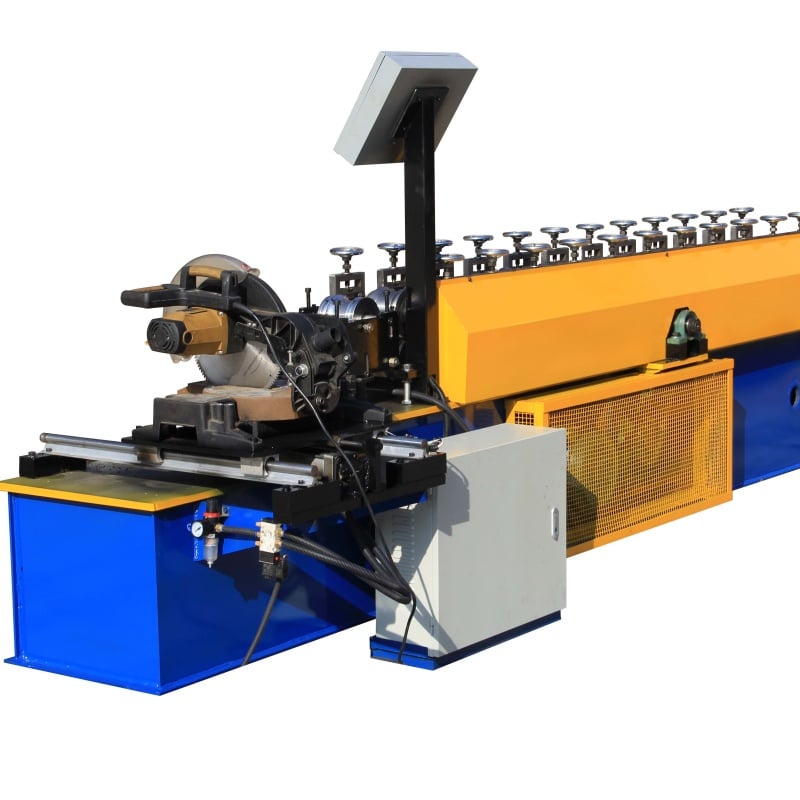

Roller shutter door roll forming machines consist of several components. The first is the un-coiler, which holds the metal coil that will be used in the process. The coil is then passed through several rollers that shape and mold it into the desired profile. The cut-off machine, the next component, then cuts the metal coil into lengths required for the roller shutter door. The machine's core unit comprises rollers, which come in different shapes and sizes to obtain different shapes and angles in the profile. Next, the punching and notching tools create drainage, ventilation, and gutter systems necessary for the door. Lastly, the stacking unit packs and transports the finished product.

The Types of Roller Shutter Door Roll Forming Machines

Two types of roller shutter door roll forming machines are the chain drive roll forming machine and the gear drive roll forming machine. The chain drive type is ideal for producing standard roller shutter doors while the gear drive type is suitable for heavy-duty doors often used in industrial and commercial settings.

The Importance of Maintenance and Servicing

Regular maintenance and servicing of the roller shutter door roll forming machine prolong its lifespan. For instance, lubrication of the working parts reduces wear and tear, while cleaning promotes hygiene and efficiency. It ensures that the machine operates optimally, and the roller shutter doors produced are of high quality.

The Applications of Roller Shutter Door Roll Forming Machines

A roller shutter door roll forming machine is used in several applications. Its main application is in the production of industrial and commercial roller shutter doors. However, roll forming machines can produce other metal profiles used in various industries such as automotive, telecommunications, and constructions.

The Future of Roller Shutter Door Roll Forming Machines

The future of roller shutter door roll forming machines is promising. Manufacturers are developing machines that are more efficient, faster, and reliable than current models. The incorporation of technology such as automation and artificial intelligence will enhance productivity, reduce costs, and improve the quality of roller shutter doors.

The Impact of Roller Shutter Door Roll Forming Machines in the Industry

Roller shutter door roll forming machines have revolutionized the production of roller shutter doors. They have made the process more efficient, faster, and reliable. Additionally, they have reduced the cost of production, making roller shutter doors affordable to many businesses. As a result, roller shutter door roll forming machines have contributed to the growth of the industrial and commercial sectors.

Conclusion

In summary, a roller shutter door roll forming machine is an essential piece of equipment in the production of roller shutter doors. It offers numerous benefits, including precision, speed, and quality. With regular maintenance and servicing, the machine will operate optimally, producing high-quality roller shutter doors. The future of roller shutter door roll forming machines is promising, with advancements in technology and increased efficiency.

Quote Inquiry

Contact Us Now!