Introduction

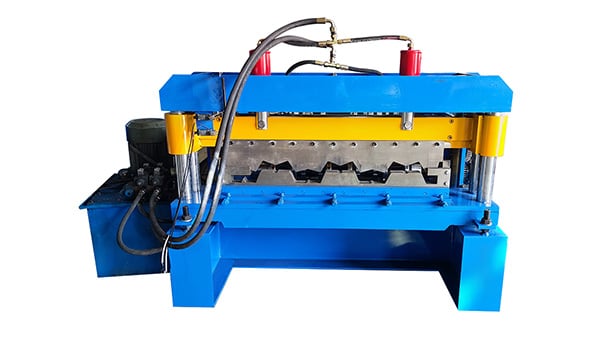

Roll forming machines are a crucial part of the manufacturing process for various industries. One such machine is the oem floor deck roll forming machine, which plays a significant role in producing floor deck panels used in construction projects. This article will explore the benefits of using an OEM floor deck roll forming machine and how it contributes to the efficiency and quality of floor deck panel production.

1. Enhanced Efficiency of Using an OEM Floor Deck Roll Forming Machine

An OEM floor deck roll forming machine is designed to streamline the production process and improve efficiency. With its automated operation, this machine can rapidly produce floor deck panels with precise dimensions. This eliminates the need for manual labor, reducing the time and effort required to manufacture these panels.

2. Consistent Quality

When it comes to manufacturing floor deck panels, consistent quality is crucial. An OEM floor deck roll forming machine ensures that every panel produced meets the required specifications. The machine's precision engineering and automated processes guarantee uniformity in panel dimensions, shape, and overall quality.

3. Versatility of Using an OEM Floor Deck Roll Forming Machine

The versatility of an OEM floor deck roll forming machine is another advantage. These machines can be customized to produce various types of floor deck panels, accommodating different project requirements. Whether it's a specific profile or a unique design, an OEM roll forming machine can be adapted to meet the demands of different construction projects.

4. Cost-effectiveness of Using an OEM Floor Deck Roll Forming Machine

Investing in an OEM floor deck roll forming machine can lead to significant cost savings in the long run. By automating the production process, manufacturers can reduce labor costs and minimize material waste. Additionally, the consistent quality of the panels ensures that there are fewer instances of rework or replacements, further reducing expenses.

5. Faster Project Completion

With an OEM floor deck roll forming machine, construction projects can be completed in a shorter timeframe. The efficient production process allows for faster panel manufacturing, enabling builders to meet tight project deadlines. This not only improves project management but also enhances overall customer satisfaction.

6. Increased Productivity of Using an OEM Floor Deck Roll Forming Machine

Productivity is a key factor in the success of any manufacturing operation. An OEM floor deck roll forming machine maximizes productivity by minimizing downtime and increasing output. With its automated processes, the machine can operate continuously, ensuring a steady flow of floor deck panels for construction projects.

7. Higher Profit Margins

By investing in an OEM floor deck roll forming machine, manufacturers can enjoy higher profit margins. The cost savings, increased productivity, and faster project completion all contribute to improved profitability. With higher profit margins, manufacturers can reinvest in their business, expand their operations, or explore new opportunities.

8. Improved Safety of Using an OEM Floor Deck Roll Forming Machine

Worker safety is a top priority in any manufacturing environment. An OEM floor deck roll forming machine reduces the risk of accidents and injuries by minimizing the need for manual labor. The automated processes eliminate the need for workers to handle heavy materials or perform physically demanding tasks, creating a safer working environment.

9. Longevity and Reliability of an OEM Floor Deck Roll Forming Machine

An OEM floor deck roll forming machine is built to last. These machines are constructed with high-quality materials and undergo rigorous testing to ensure their durability and reliability. Investing in a reliable machine reduces the chances of breakdowns or malfunctions, allowing manufacturers to meet production targets consistently.

10. Environmental Benefits of an OEM Floor Deck Roll Forming Machine

Lastly, an OEM floor deck roll forming machine offers environmental benefits. By reducing material waste and optimizing energy consumption, these machines contribute to a more sustainable manufacturing process. As the world becomes increasingly conscious of environmental concerns, investing in eco-friendly manufacturing equipment can help businesses align with sustainability goals.