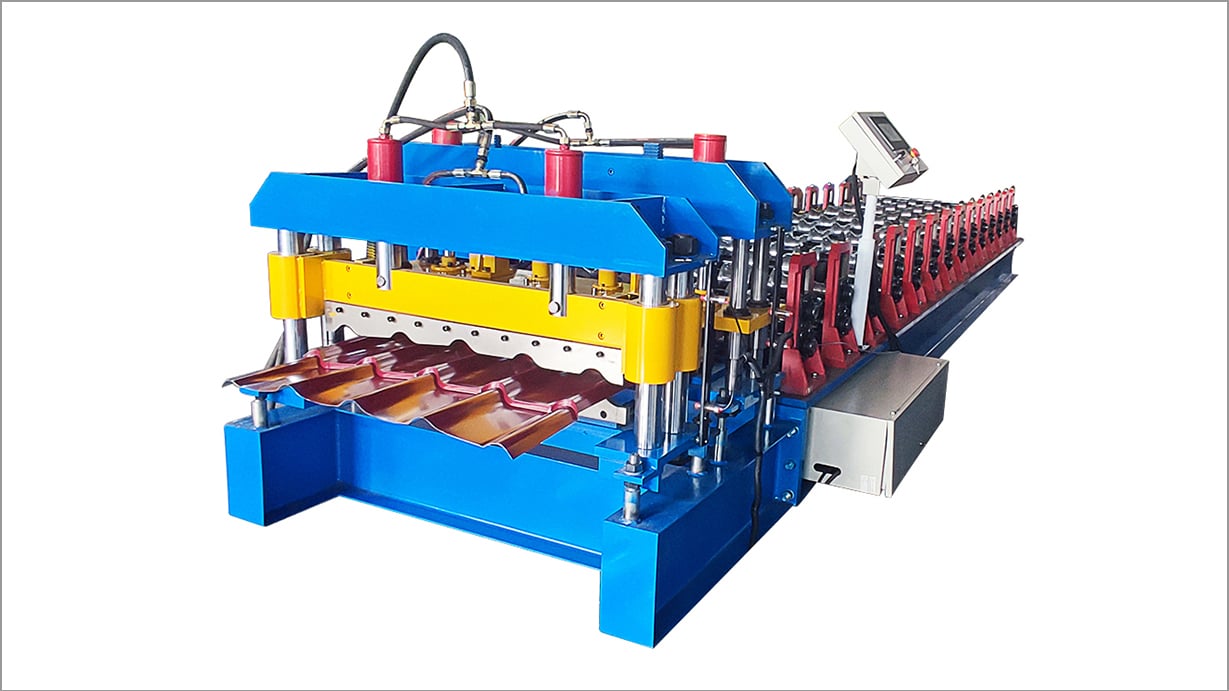

1. The Role of a glazed tile roll forming machine manufacturer in the Construction Industry

A glazed tile roll forming machine is an essential piece of equipment in the construction industry. It is used to efficiently produce glazed tiles, which are widely used in residential and commercial buildings. The quality of the machine plays a crucial role in the final product's durability, efficiency, and overall appearance. This article explores the importance of choosing a reliable glazed tile roll forming machine manufacturer and the factors to consider.

2. The Benefits of Working with a Reputable Manufacturer

Working with a reputable glazed tile roll forming machine manufacturer offers numerous benefits. Firstly, reputable manufacturers have a track record of producing high-quality machines that meet industry standards. Their machines are designed to be durable, long-lasting, and efficient, ensuring minimal downtime and maximum productivity.

3. Quality Assurance and Compliance

A reliable glazed tile roll forming machine manufacturer understands the importance of quality assurance and compliance. They adhere to strict manufacturing processes and quality control measures to ensure that each machine meets the required standards. This commitment to quality ensures that the machines are safe to operate, produce consistent results, and have a longer lifespan.

4. Technological Advancements and Innovation

Choosing a reputable manufacturer guarantees access to the latest technological advancements and innovations in glazed tile roll forming machines. These manufacturers invest heavily in research and development to stay ahead of the competition. They continuously improve their machines, incorporating new features and technologies that enhance efficiency, precision, and overall performance.

5. Customization and Flexibility of a glazed tile roll forming machine

A reliable glazed tile roll forming machine manufacturer understands that different customers have unique requirements. They offer customization options to tailor the machine according to specific needs. Whether it's adjusting the dimensions, speed, or other parameters, a reputable manufacturer can accommodate these requests, providing a more personalized solution.

6. After-Sales Support and Service

After-sales support and service are crucial factors to consider when choosing a glazed tile roll forming machine manufacturer. Reputable manufacturers offer comprehensive support, including installation assistance, operator training, and troubleshooting services. This ensures that customers can quickly resolve any issues that arise and maximize the machine's efficiency.

7. Warranty and Spare Parts Availability

A reliable manufacturer stands behind their products by offering warranty coverage. This provides peace of mind to customers, knowing that any potential defects or malfunctions will be addressed without additional cost. Additionally, reputable manufacturers maintain a stock of spare parts, ensuring that replacements are readily available when needed.

8. Industry Expertise and Experience

Choosing a glazed tile roll forming machine manufacturer with industry expertise and experience is essential. These manufacturers have a deep understanding of the construction industry's requirements and can provide valuable insights and guidance. Their experience allows them to anticipate potential challenges and offer effective solutions.

9. Reputation and Customer Reviews

Before making a decision, it is important to research the reputation of a glazed tile roll forming machine manufacturer. Check customer reviews and testimonials to gauge their satisfaction levels. A manufacturer with positive reviews and a strong reputation is more likely to deliver a reliable and high-quality machine.

10. Cost-Effectiveness and Return on Investment

While the initial cost of a glazed tile roll forming machine is a significant investment, choosing a reliable manufacturer ensures long-term cost-effectiveness. High-quality machines require less maintenance and repair, resulting in reduced downtime and increased productivity. Additionally, the durability and efficiency of these machines result in a higher return on investment over time.