Introduction

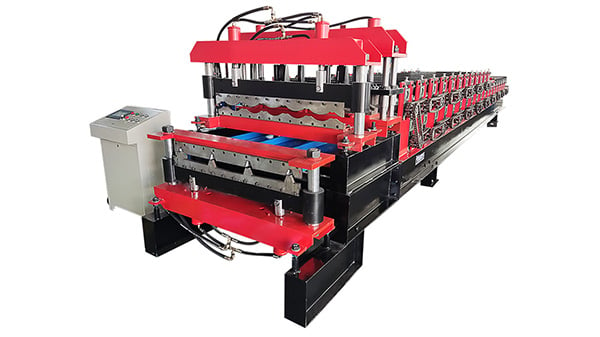

In the world of manufacturing, efficiency and precision are key factors that contribute to the success of any production line. One such innovation that has revolutionized the metal forming industry is the customized automic double layer roll forming machine. This advanced machinery offers a wide range of benefits, including increased productivity, accuracy, and flexibility. In this article, we will explore the various aspects of this cutting-edge technology and its significance in the manufacturing sector.

1. Understanding Roll Forming

Before delving into the details of customized automic double layer roll forming machines, it is essential to have a basic understanding of roll forming. Roll forming is a process used to shape metal sheets into desired profiles by passing them through a series of rollers. This method is widely used in various industries, including automotive, construction, and appliance manufacturing.

2. The Power of Customization

One of the key advantages of the customized automic double layer roll forming machine is its ability to offer a high level of customization. This means that manufacturers can tailor the machine to meet their specific requirements and produce a wide range of profiles. Whether it's complex shapes, different thicknesses, or unique designs, this machine can handle it all with ease.

3. Automation for Enhanced Efficiency

The term "automic" in the customized automic double layer roll forming machine refers to its automation capabilities. By incorporating advanced control systems and sensors, this machine can perform tasks with minimal human intervention. This automation not only improves efficiency but also reduces the risk of errors, resulting in higher quality products and increased productivity.

4. Double Layer roll forming for Increased Productivity

The double layer feature of this roll forming machine allows for simultaneous production of two different profiles. This significantly boosts productivity as it eliminates the need for multiple machines or time-consuming manual adjustments. By maximizing the use of available resources, manufacturers can achieve higher output rates and meet tight production deadlines.

5. Roll Forming Machine for Diverse Materials

Another noteworthy aspect of the customized automic double layer roll forming machine is its versatility in handling various materials. Whether it's steel, aluminum, copper, or even composite materials, this machine can efficiently process them all. This flexibility enables manufacturers to cater to a wide range of industries and expand their market reach.

6. Precision and Accuracy

When it comes to roll forming, precision and accuracy are paramount. The customized automic double layer roll forming machine excels in this aspect by offering tight tolerances and consistent results. With advanced monitoring and control systems, manufacturers can ensure that each profile meets the required specifications, resulting in high-quality end products.

7. Integration with CAD/CAM Software

To further enhance the capabilities of the customized automic double layer roll forming machine, it can be seamlessly integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration allows for efficient design transfer, optimized material usage, and real-time monitoring of the production process. Manufacturers can easily create, modify, and simulate profiles, streamlining the entire manufacturing workflow.

8. Flexibility for Future Expansion

The customized automic double layer roll forming machine is designed to adapt to changing manufacturing demands. It offers flexibility in terms of adjustments, tooling changes, and profile modifications. This future-proof feature ensures that manufacturers can easily accommodate new product designs and expand their production capabilities without major investments in additional machinery.

9. Cost-Effectiveness and Return on Investment

Investing in a customized automic double layer roll forming machine can yield significant cost savings in the long run. With its high efficiency, reduced material waste, and minimal maintenance requirements, manufacturers can achieve a favorable return on investment. The increased productivity and quality of the end products also contribute to improved customer satisfaction and market competitiveness.

10. Conclusion

The customized automic double layer roll forming machine is a game-changer in the manufacturing industry. Its ability to offer customization, automation, and increased productivity makes it an indispensable tool for metal forming processes. By harnessing the power of this advanced technology, manufacturers can stay ahead of the competition, meet evolving market demands, and propel their businesses to new heights.