double layer roofing sheet roll forming machine: A Comprehensive Guide

When it comes to the construction industry, efficiency and precision are of utmost importance. One of the crucial aspects of any building project is the roof, and selecting the right material can significantly impact the overall quality and durability of the structure. In recent years, the use of double layer roofing sheet roll forming machines has gained popularity due to their ability to produce high-quality roofing sheets efficiently. In this article, we will explore the various aspects of double layer roofing sheet roll forming machines and their benefits in construction projects.

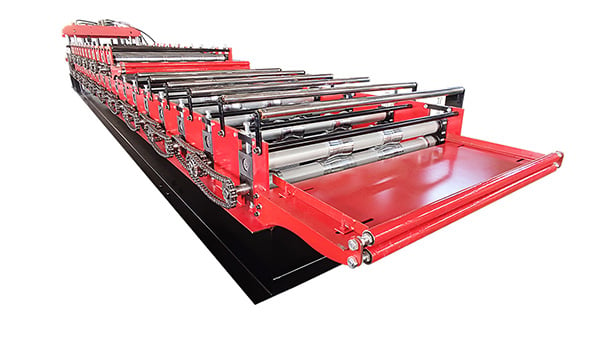

The Basics of Double Layer Roofing Sheet Roll Forming Machines

Double layer roofing sheet roll forming machines are advanced equipment used in the manufacturing process of roofing sheets. These machines utilize a continuous bending operation to produce sheets with consistent profiles and dimensions. The double layer feature allows for the production of two different profiles simultaneously, which is ideal for projects requiring different types of roofing sheets. This technology enables manufacturers to streamline their production process and meet the diverse needs of customers.

The Advantages of Double Layer Roofing Sheet Roll Forming Machines

Investing in a double layer roofing sheet roll forming machine comes with numerous benefits for manufacturers and construction professionals. Here are some advantages:

1. Increased Efficiency

Double layer roofing sheet roll forming machines are designed to optimize production efficiency. By producing two different profiles simultaneously, manufacturers can reduce production time and meet tight deadlines. The automated operation of these machines also minimizes the need for manual labor, saving both time and resources.

2. Cost-Effective Solution

With the ability to produce high-quality roofing sheets at a rapid pace, double layer roll forming machines offer a cost-effective solution for manufacturers. By reducing labor costs and increasing productivity, these machines contribute to higher profit margins.

3. Versatility in Design

Double layer roofing sheet roll forming machines allow for the creation of various designs and profiles. Manufacturers can customize the roofing sheets based on the specific requirements of each project. This versatility enables architects and contractors to bring their creative visions to life.

4. Consistent Quality

One of the key advantages of double layer roofing sheet roll forming machines is their ability to produce sheets with consistent profiles and dimensions. This consistency ensures that every roofing sheet is of high quality and meets industry standards. By eliminating variations in the manufacturing process, these machines contribute to the overall durability and reliability of the roofing sheets.

5. Durability and Longevity

Roofing sheets produced by double layer roll forming machines are known for their durability and longevity. These sheets are designed to withstand harsh weather conditions, including heavy rain, strong winds, and extreme temperatures. This durability reduces the need for frequent repairs or replacements, saving both time and money for building owners.

Choosing the Right Double Layer Roofing Sheet Roll Forming Machine

When selecting a double layer roofing sheet roll forming machine, several factors need to be considered:

1. Production Capacity

Determine the required production capacity based on the volume of roofing sheets needed for your projects. Consider both current and future demands to ensure that the machine can meet your long-term production needs.

2. Speed and Efficiency

Assess the speed and efficiency of the machine to ensure that it aligns with your production goals. Look for features such as automatic material feeding and cutting to maximize efficiency and reduce manual labor.

3. Customization Options

Check if the machine allows for customization of profiles and designs. This flexibility is crucial for meeting the specific requirements of different projects and accommodating architectural preferences.

4. Reliability and Service

Research the reputation and reliability of the manufacturer or supplier. Assess their after-sales service and support to ensure that any potential issues or maintenance requirements can be addressed promptly.

In Conclusion

Double layer roofing sheet roll forming machines have revolutionized the roofing industry by offering a cost-effective and efficient solution for manufacturing high-quality roofing sheets. The advantages of these machines, including increased efficiency, versatility in design, and consistent quality, make them a valuable asset for manufacturers and construction professionals. By investing in the right machine and considering factors such as production capacity and customization options, businesses can enhance their productivity and deliver exceptional roofing solutions.