Introduction

Welcome to our comprehensive guide on glazed roof tile roll forming machines. In this article, we will explore the various aspects of these machines, including their functionality, benefits, and applications. Whether you are a roofing contractor or a DIY enthusiast, understanding the capabilities of glazed roof tile roll forming machines can help you make informed decisions for your projects.

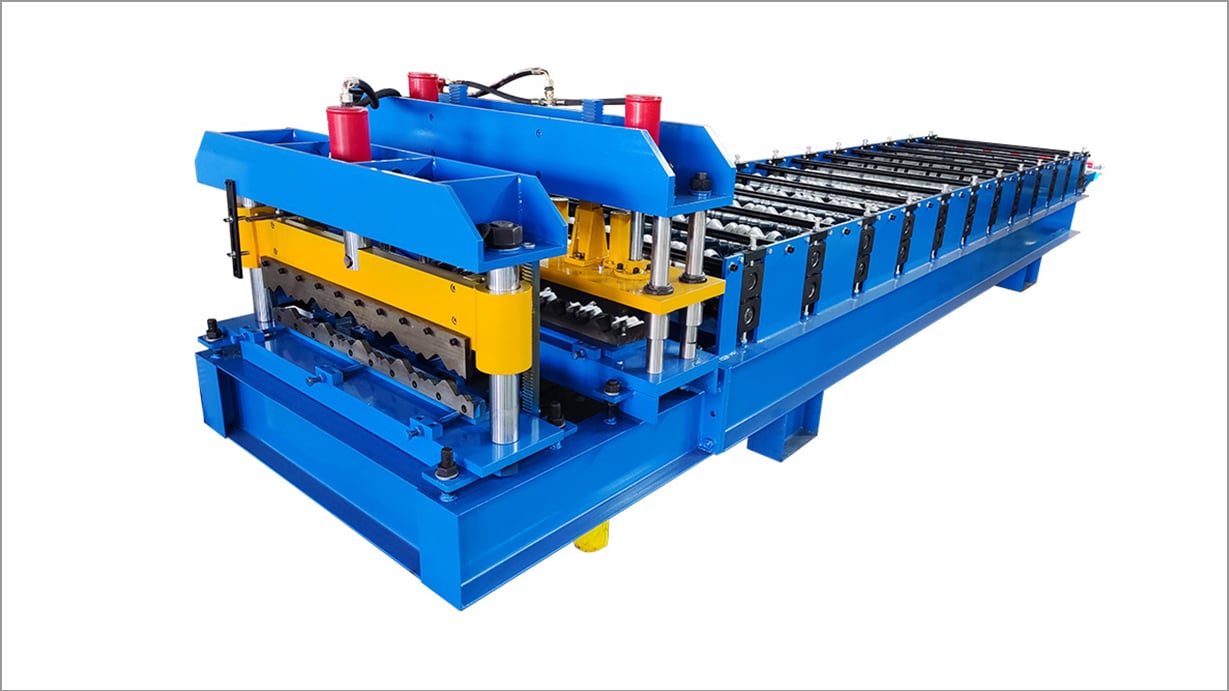

1. What is a Glazed Roof Tile Roll Forming Machine?

A glazed roof tile roll forming machine is a specialized equipment used in the manufacturing process of glazed roof tiles. It utilizes a continuous bending operation to produce uniform and precise roof tiles with a glazed surface. The machine takes raw materials, such as metal coils or sheets, and transforms them into finished glazed roof tiles.

2. How Does a Glazed Roof Tile Roll Forming Machine Work?

The working principle of a glazed roof tile roll forming machine involves several steps. First, the raw material is fed into the machine, where it passes through a series of rollers. These rollers gradually shape the material into the desired profile, which is the shape of the glazed roof tile. The glazed surface is typically applied during the forming process using a specialized coating system. Finally, the machine cuts the formed tiles into the desired lengths.

3. Advantages of Glazed Roof Tile Roll Forming Machines

Glazed roof tile roll forming machines offer numerous advantages over traditional tile manufacturing methods. Firstly, they provide high production efficiency, allowing for the continuous and rapid production of roof tiles. Additionally, these machines offer excellent precision and consistency, ensuring that each tile has a uniform shape and glazed surface. Furthermore, glazed roof tile roll forming machines are highly customizable, allowing for the production of various tile profiles and sizes.

4. Applications of Glazed Roof Tile Roll Forming Machines

Glazed roof tile roll forming machines are widely used in the construction industry for various applications. They are primarily employed in residential, commercial, and industrial roofing projects. Glazed roof tiles are known for their aesthetic appeal and durability, making them a popular choice for both new construction and renovation projects. These machines can produce tiles with different profiles, colors, and finishes, providing architects and homeowners with a wide range of design options.

5. Factors to Consider When Choosing a Glazed Roof Tile Roll Forming Machine

When selecting a glazed roof tile roll forming machine, several factors should be taken into consideration. Firstly, consider the required production capacity, as different machines have varying output capabilities. Additionally, assess the material compatibility, as some machines may be better suited for specific materials like steel or aluminum. Other factors to consider include the machine's reliability, ease of operation, and maintenance requirements.

6. Maintenance and Care for Glazed Roof Tile Roll Forming Machines

Proper maintenance and care are essential to ensure the longevity and optimal performance of glazed roof tile roll forming machines. Regular inspection and cleaning of the machine's components, such as rollers and cutting blades, help prevent debris buildup and minimize wear and tear. Lubrication of moving parts and timely replacement of worn-out components are also crucial to maintain the machine's efficiency and accuracy.

7. Safety Considerations for Glazed Roof Tile Roll Forming Machines

Working with any machinery involves certain risks, and glazed roof tile roll forming machines are no exception. It is crucial to follow all safety guidelines and precautions when operating these machines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses. Operators should also receive proper training on the machine's operation and safety procedures to prevent accidents and injuries.

8. Emerging Trends in Glazed Roof Tile Roll Forming Machines

The field of glazed roof tile roll forming machines is continuously evolving, with new developments and trends emerging. One notable trend is the integration of advanced automation technology, which allows for greater precision, efficiency, and control in the manufacturing process. Additionally, there is a growing focus on sustainability, with manufacturers exploring eco-friendly materials and energy-efficient production methods.

9. Choosing the Right Manufacturer for Glazed Roof Tile Roll Forming Machines

When investing in a glazed roof tile roll forming machine, it is essential to choose a reputable and reliable manufacturer. Look for manufacturers with a proven track record in the industry and positive customer reviews. Consider their experience, technical expertise, and after-sales support. A trusted manufacturer will provide quality machines, comprehensive training, and prompt technical assistance when needed.

10. Conclusion

Glazed roof tile roll forming machines are indispensable tools for the production of high-quality roof tiles with a glazed surface. They offer numerous advantages, including efficiency, precision, and customization options. By understanding the working principles, applications, and maintenance considerations of these machines, you can make informed decisions and achieve outstanding results in your roofing projects.