The Ultimate Guide to glazed tile roll forming machine: Everything You Need to Know

Introduction:

Glazed tile roll forming machines have revolutionized the roofing industry, making it easier and more efficient to produce high-quality glazed tiles. In this comprehensive guide, we will explore everything you need to know about glazed tile roll forming machines, from their functionality and benefits to the different types available in the market. Whether you are a roofing contractor, a construction professional, or simply interested in the technology behind these machines, this guide will provide you with valuable insights.

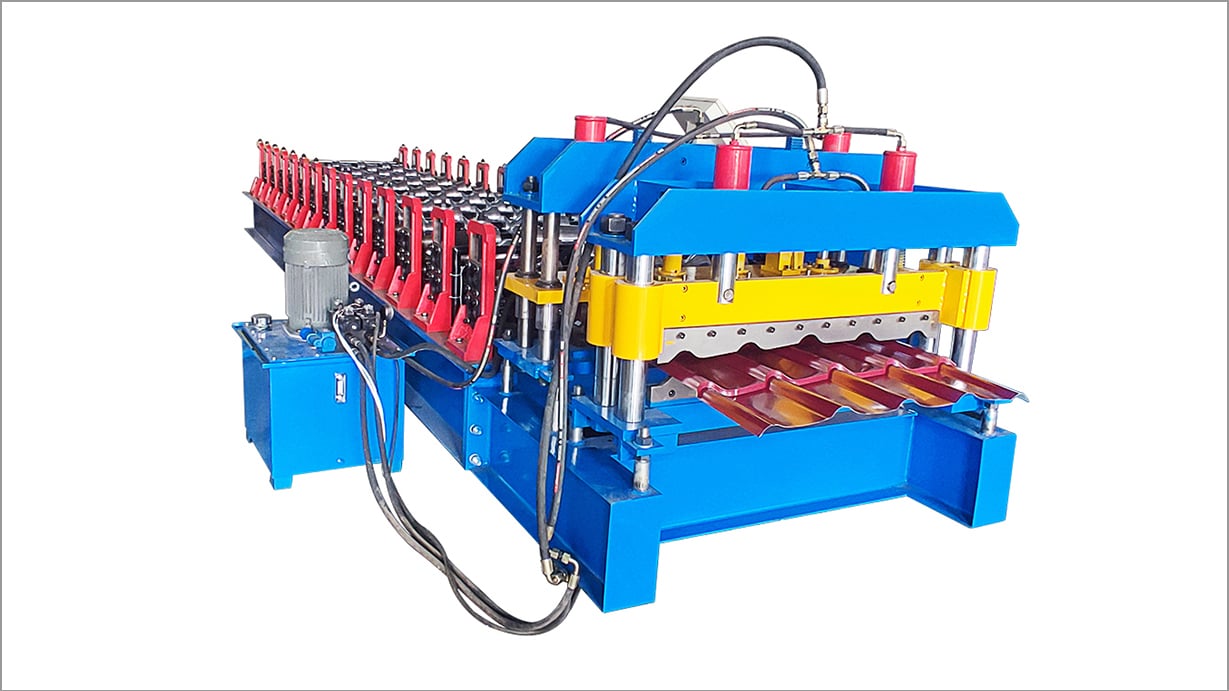

1. What is a Glazed Tile Roll Forming Machine?

Glazed tile roll forming machines are specialized equipment used to manufacture glazed tiles, which are commonly used in roofing applications. These machines automate the process of roll forming, which involves the continuous bending of metal sheets into specific shapes, in this case, glazed tiles. The machine takes a flat metal sheet as input and forms it into a desired profile, ensuring uniformity and precision in the final product.

2. How Does a Glazed Tile Roll Forming Machine Work?

The working principle of a glazed tile roll forming machine is relatively simple yet highly efficient. The machine consists of a series of rollers and other components that progressively shape the metal sheet into the desired tile profile. The metal sheet is fed into the machine, and as it passes through the rollers, it undergoes a series of bending and shaping operations. These operations are carefully calibrated to ensure the accurate formation of the glazed tile profile.

3. Benefits of Using Glazed Tile Roll Forming Machines

Using glazed tile roll forming machines offers numerous benefits to both manufacturers and end-users:

- Efficiency: Roll forming machines can produce glazed tiles at a much faster rate compared to traditional manual methods, significantly reducing production time and labor costs.

- Precision: These machines are designed to deliver high precision and accuracy, ensuring that every glazed tile produced meets the required specifications.

- Consistency: By automating the roll forming process, glazed tile roll forming machines deliver consistent results, eliminating variations commonly associated with manual production methods.

- Flexibility: These machines can be easily adjusted to produce different tile profiles, allowing manufacturers to meet diverse customer demands efficiently.

4. Types of Glazed Tile Roll Forming Machines

There are several types of glazed tile roll forming machines available in the market, each catering to different production requirements and specifications. Some common types include:

- Single Layer Glazed Tile Roll Forming Machine: This type of machine is designed to produce single-layer glazed tiles, which are ideal for residential roofing applications.

- Double Layer Glazed Tile Roll Forming Machine: As the name suggests, this machine can produce double-layer glazed tiles, providing added durability and insulation properties.

- High-Speed Glazed Tile Roll Forming Machine: This machine is specifically designed for high-volume production, offering increased efficiency and productivity.

5. Key Components of a Glazed Tile Roll Forming Machine

A glazed tile roll forming machine consists of several key components that work together to ensure smooth and efficient operation:

- Decoiler: This component holds the metal coil and feeds it into the roll forming machine.

- Rollers: The rollers are responsible for shaping the metal sheet into the desired tile profile.

- Cutting System: Once the tile profile is formed, the cutting system trims the excess material and separates the individual tiles.

- Control System: This system controls the overall operation of the machine, including speed, length, and other parameters.

6. Maintenance and Care for Glazed Tile Roll Forming Machines

Regular maintenance and care are essential to ensure the longevity and optimal performance of glazed tile roll forming machines. Here are some important tips:

- Cleaning: Regularly clean the machine to remove dust, debris, and accumulated materials that can affect its performance.

- Lubrication: Apply lubricants to the moving parts to reduce friction and prevent premature wear and tear.

- Inspection: Regularly inspect the machine for any signs of damage or wear and address them promptly to avoid further issues.

- Training: Train operators on proper machine operation and maintenance procedures to ensure safe and efficient use.

7. Applications of Glazed Tiles

Glazed tiles produced using roll forming machines find a wide range of applications in the construction industry:

- Roofing: Glazed tiles are commonly used for residential and commercial roofing due to their aesthetic appeal, durability, and weather resistance.

- Wall Cladding: Glazed tiles can also be used for decorative wall cladding, providing an attractive and durable finish to buildings.

- Flooring: In some cases, glazed tiles are used for flooring applications, especially in areas that require a high level of resistance to wear and tear.

8. Cost Considerations for Glazed Tile Roll Forming Machines

The cost of glazed tile roll forming machines can vary depending on various factors, including the machine's type, production capacity, and additional features. It is essential to consider the long-term benefits and return on investment when evaluating the cost of these machines. While initial investment may be higher compared to manual methods, the increased efficiency, consistency, and reduced labor costs can lead to significant savings over time.

9. Choosing the Right Glazed Tile Roll Forming Machine

When selecting a glazed tile roll forming machine, it is crucial to consider your specific production requirements, budget constraints, and the reputation of the manufacturer. Look for a machine that offers the necessary features, customization options, and reliable after-sales support.

10. Conclusion

Glazed tile roll forming machines have revolutionized the roofing industry, providing a cost-effective and efficient solution for producing high-quality glazed tiles. Understanding the working principle, benefits, types, and maintenance requirements of these machines is essential for anyone involved in the roofing or construction industry. By investing in the right glazed tile roll forming machine and following proper maintenance procedures, manufacturers can enhance their productivity, streamline their operations, and deliver superior products to their customers.