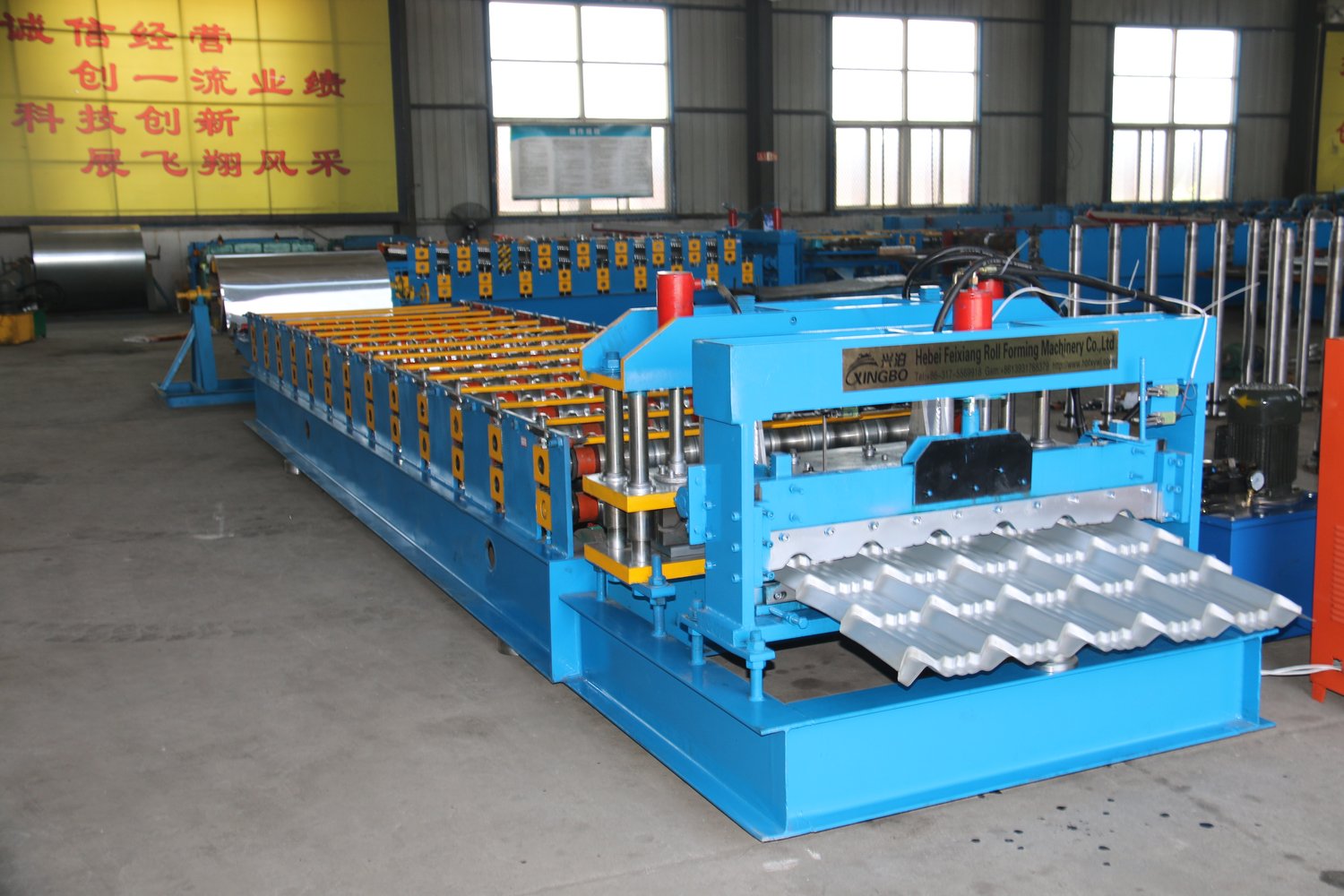

What is a roll forming machine?

A roll forming machine is a specialized piece of equipment used in the metalworking industry to produce continuous metal profiles with a uniform cross-section. It is a cost-effective and efficient manufacturing process that involves feeding a metal strip or coil through a series of roll dies to gradually shape the metal into the desired profile.

The Working Principle of a Roll Forming Machine

Roll forming machines work on a continuous process, where the metal strip or coil is fed into the machine and passed through a series of roll dies. These roll dies are designed to progressively bend and form the metal into the desired shape. Each roll die in the machine performs a specific bending or forming operation, and they are arranged in a sequence along the machine's length.

The Advantages of Using a Roll Forming Machine

Roll forming machines offer several advantages over other metal forming techniques:

- High Efficiency: Roll forming machines can produce profiles at high speeds, making them suitable for large-scale production.

- Flexibility: The machine can be easily adjusted to produce different profiles by changing the roll dies.

- Cost-Effective: Roll forming eliminates the need for expensive secondary operations, reducing production costs.

- Precision and Consistency: Roll forming ensures consistent dimensions and high-quality finishes on the produced profiles.

- Material Savings: The process minimizes material waste, resulting in cost savings.

Applications of Roll Forming Machines

Roll forming machines find applications in various industries, including:

- Construction: Roll formed profiles are widely used in the construction of buildings, bridges, and infrastructure.

- Automotive: The automotive industry utilizes roll formed parts in vehicle frames, doors, and roof rails.

- Storage Systems: Roll formed components are used in the production of shelves, racks, and storage systems.

- Appliances: Roll formed parts are commonly found in appliances such as refrigerators, ovens, and washing machines.

- Furniture: Roll formed profiles are used in the manufacturing of furniture, including tables, chairs, and cabinets.

Types of Roll Forming Machines

There are different types of roll forming machines available, each designed for specific applications:

- Single-Station Machines: These machines have a single set of roll dies and are suitable for producing simple profiles.

- Progressive Machines: Progressive roll forming machines have multiple roll die stations, allowing the production of complex profiles in a single pass.

- Custom Machines: Custom roll forming machines are designed and built to meet specific requirements and produce unique profiles.

Factors to Consider When Choosing a Roll Forming Machine

When selecting a roll forming machine for your manufacturing needs, consider the following factors:

- Material: Ensure that the machine is suitable for the type and thickness of metal you intend to use.

- Profile Complexity: Determine if the machine can produce the desired profile, considering its complexity and dimensions.

- Production Volume: Choose a machine that can handle your desired production volume without compromising efficiency.

- Machine Size and Power: Consider the available space in your facility and the power requirements of the machine.

- Automation and Control: Evaluate the level of automation and control features offered by the machine.

Maintenance and Care of Roll Forming Machines

To ensure optimal performance and longevity of your roll forming machine, regular maintenance is essential. Key maintenance tasks include:

- Cleaning: Keep the machine clean from dust, debris, and metal shavings that can affect its performance.

- Lubrication: Apply lubricants to the moving parts of the machine to reduce friction and prevent premature wear.

- Inspection: Regularly inspect the machine's components for signs of wear or damage and replace them as necessary.

- Alignment: Ensure that the machine's roll dies and other components are properly aligned to maintain accurate profile production.

In Conclusion

A roll forming machine is a versatile and efficient tool used in the metalworking industry to produce continuous metal profiles with a uniform cross-section. With its numerous advantages, including high efficiency, flexibility, and cost-effectiveness, roll forming machines have become an integral part of various industries. When choosing a roll forming machine, consider factors such as the material, profile complexity, production volume, machine size, and automation features. Regular maintenance and care are crucial to ensure the machine's optimal performance and longevity.