Introduction to Purlin Machine

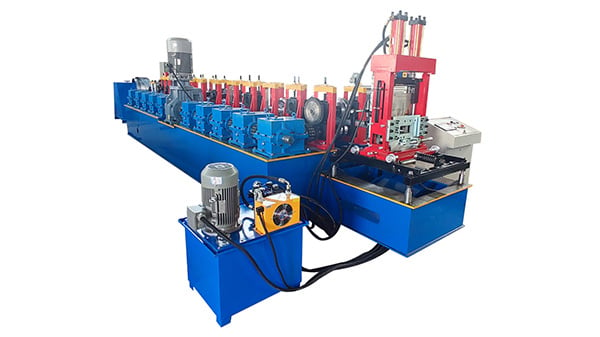

A purlin machine is a specialized piece of equipment used in the construction industry to produce purlins, which are structural members used to support the roof of a building. Purlins are typically made of steel and are installed horizontally across the length of the roof, providing support for the roof covering and transferring the load to the primary roof framing members.

1. How Does a Purlin Machine Work?

A purlin machine is designed to automate the process of producing purlins. It consists of a series of rollers and dies that shape and bend the steel coil into the desired purlin profile. The machine operates by feeding the steel coil through the rollers, which gradually form the steel into the required shape. The process is highly efficient and can produce purlins with consistent dimensions and quality.

2. Types of Purlin Machines

There are various types of purlin machines available in the market, each designed to produce different types of purlin profiles. Some common types include C purlin machines, Z purlin machines, and U purlin machines. These machines can produce purlins with different dimensions, shapes, and thicknesses, depending on the specific requirements of the building.

3. Advantages of Using a Purlin Machine

Using a purlin machine offers several advantages over traditional methods of producing purlins manually. Firstly, it significantly reduces labor costs and improves production efficiency. The machine can produce purlins at a much faster rate, allowing construction projects to be completed more quickly. Additionally, the automated process ensures consistent quality, reducing the risk of errors and defects.

4. Applications of Purlin Machine

Purlin machines are widely used in the construction industry for various applications. They are primarily used in the construction of industrial buildings, warehouses, and commercial structures. Purlins provide structural support to the roof, enabling it to withstand the weight of the roof covering, as well as external forces such as wind and snow loads.

5. Factors to Consider When Choosing a Purlin Machine

When selecting a purlin machine, there are several factors to consider. These include the required purlin profile, production capacity, material thickness, and the overall reliability and durability of the machine. It is important to choose a machine that meets the specific requirements of the project and can deliver high-quality purlins consistently.

6. Maintenance and Care of Purlin Machines

To ensure the optimal performance and longevity of a purlin machine, regular maintenance and care are essential. This includes routine inspections, lubrication of moving parts, and timely replacement of worn-out components. It is also important to follow the manufacturer's guidelines and recommendations for proper operation and maintenance.

7. Future Trends in Purlin Machine Technology

The technology used in purlin machines is continuously evolving, with new advancements and innovations being introduced. Some future trends in purlin machine technology include the integration of advanced automation and control systems, improved energy efficiency, and the development of machines capable of producing a wider range of purlin profiles.

8. Cost Considerations of Purlin Machines

The cost of a purlin machine can vary depending on factors such as the machine's specifications, brand, and additional features. It is important to consider the long-term benefits and cost savings that can be achieved through increased productivity and reduced labor costs when evaluating the investment in a purlin machine.

9. Training and Support for Purlin Machine Operators

Proper training and support for operators are crucial to ensure safe and efficient operation of the purlin machine. Manufacturers often provide training programs and technical support to help operators familiarize themselves with the machine's operation, maintenance, and troubleshooting. It is important for operators to follow all safety guidelines and receive periodic training updates.

10. Conclusion

A purlin machine is a valuable tool in the construction industry, offering numerous advantages in terms of efficiency, quality, and cost-effectiveness. By automating the production of purlins, construction projects can be completed faster and with greater precision. Investing in a purlin machine can be a wise decision for construction companies looking to streamline their operations and enhance their competitiveness in the market.