What is the process of roll forming??

Introduction:

Roll forming is a highly efficient and versatile metal forming process used in various industries, including automotive, construction, and manufacturing. It involves progressively bending metal strips or sheets into complex shapes using a series of rolling dies. This article will provide a detailed overview of the roll forming process, its benefits, and its applications.

The Basics of Roll Forming

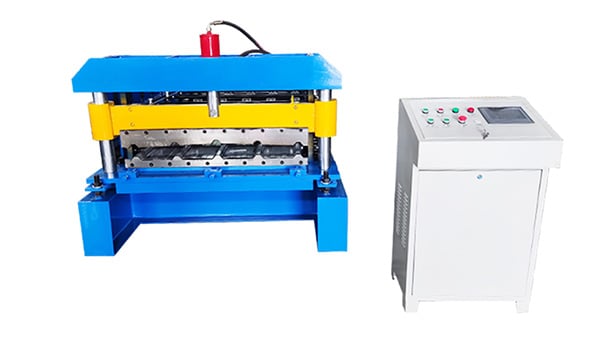

Roll forming is a continuous process that involves feeding a metal strip or sheet through a series of rollers, or forming stands. These rollers gradually shape the metal into the desired profile, such as a channel, angle, or tube. The roll forming machine consists of several components, including the entry guide, leveling unit, forming stands, cut-off press, and exit guide.

Step 1: Material Preparation

Prior to the roll forming process, the metal material needs to be prepared. This includes selecting the appropriate metal alloy and thickness for the desired application. The metal strip or sheet is typically uncoiled from a coil and fed into the roll forming machine.

Step 2: Feeding and Leveling

Once the material is prepared, it is fed into the roll forming machine through the entry guide. The entry guide ensures proper alignment and positioning of the material before it enters the forming stands. The leveling unit then straightens and flattens the material to ensure consistent and accurate forming.

Step 3: Forming Stands

The heart of the roll forming process lies in the forming stands. These stands consist of a series of rollers, each performing a specific bending operation. As the material passes through the forming stands, it gradually takes on the desired shape. Each stand bends the material slightly, and the cumulative effect of all the stands results in the final profile.

Step 4: Cut-off Press

Once the material has been formed into the desired shape, it reaches the cut-off press. This press cuts the continuous profile into individual lengths or pieces. The cut-off press is synchronized with the speed of the roll forming machine to ensure precise cutting.

Step 5: Exit Guide and Stacking

After the cut-off press, the formed pieces are guided out of the roll forming machine through the exit guide. Depending on the application, the pieces may be stacked, packaged, or further processed. The exit guide ensures smooth handling and prevents damage to the formed profiles.

Benefits of Roll Forming

Roll forming offers numerous advantages over other metal forming processes:

- High efficiency: Roll forming is a continuous process that allows for high-speed production.

- Cost-effective: It eliminates the need for multiple individual operations, reducing labor and tooling costs.

- Versatility: Roll forming can produce complex shapes with consistent quality, including custom profiles.

- Material savings: The roll forming process minimizes material waste compared to other forming methods.

- Design flexibility: It enables the production of long lengths of uniform profiles, ideal for various applications.

Applications of Roll Forming

Roll forming finds wide-ranging applications across various industries:

- Automotive: Roll-formed components are used in car frames, roof rails, and structural reinforcements.

- Construction: It is utilized in the production of metal roofing, wall panels, and structural sections.

- Storage systems: Roll-formed profiles are commonly used in shelving, racking, and storage systems.

- Appliances: Roll-formed parts can be found in appliances like refrigerators, ovens, and air conditioning units.

- Furniture: It is employed in the manufacturing of metal furniture, such as desks, cabinets, and shelves.

roll forming, metal forming process, roll forming machine, forming stands, cut-off press, benefits of roll forming, applications of roll forming Understanding the Roll Forming Process: A Comprehensive Guide Discover the step-by-step process of roll forming and explore its benefits and applications. Get insights into the efficiency, versatility, and cost-effectiveness of this metal forming process.