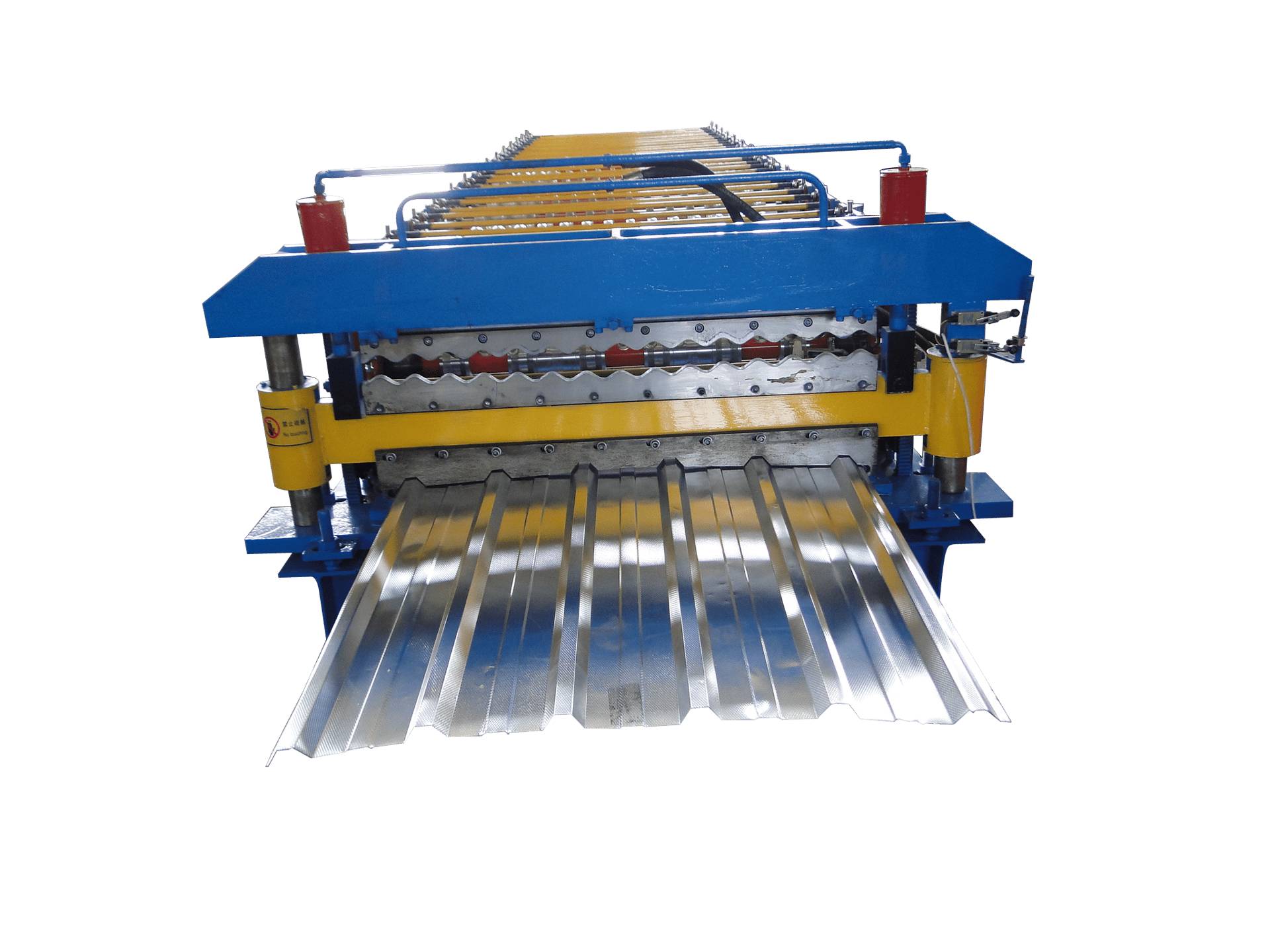

Dual thickness roll forming equipment

We provide free samples, you just need to cover the shipping cost. We sincerely look forward to cooperating with you for mutual benefit, and please contact us for any other questions.

Original Design Manufacturer

Manufacturing of metal cold forming equipment

One-stop sales and support services

Dual Thickness Roll Forming Equipment: A Game-Changer in Metal Fabrication

Introduction:

Roll forming is a widely used metal fabrication process that involves continuous bending and shaping of metal strips into desired profiles. The advent of dual thickness roll forming equipment has revolutionized the industry by offering enhanced flexibility and efficiency in producing profiles with variable thicknesses. This article explores the various advantages and applications of this game-changing technology.

Understanding Dual Thickness Roll Forming Equipment

Dual thickness roll forming equipment is designed to handle metal strips with different thicknesses during the roll forming process. Unlike traditional roll forming machines that work with a fixed thickness, dual thickness equipment can seamlessly switch between profiles with varying thicknesses. This versatility eliminates the need for manual adjustments or switching between different machines, saving both time and labor costs.

Advantages of Dual Thickness Roll Forming

The utilization of dual thickness roll forming equipment offers several advantages to metal fabricators. Firstly, it enables the production of complex profiles that require multiple thicknesses in a single run. This eliminates the need for post-processing or joining separate components, resulting in a more efficient and cost-effective manufacturing process. Secondly, the ability to switch between different thicknesses on the same machine enables manufacturers to adapt quickly to changing customer demands and market trends. This flexibility helps them stay competitive and responsive in a dynamic industry.

Applications in Various Industries

Dual thickness roll forming equipment finds applications in a wide range of industries. One prominent sector is the automotive industry, where the demand for lightweight and strong components is increasing. This equipment allows manufacturers to produce automotive parts with variable thicknesses, such as structural beams or body panels, in a single operation. Similarly, the construction industry benefits from this technology by enabling the production of profiles with varying thicknesses for applications like roofing, wall cladding, and structural supports.

Considerations for Implementing Dual Thickness Roll Forming

While dual thickness roll forming offers numerous advantages, there are some factors to consider when implementing this technology. Manufacturers need to ensure that their roll forming equipment is capable of handling varying thicknesses without compromising the quality of the profiles. Proper calibration and maintenance of the machine are crucial for achieving consistent and precise results. Additionally, training operators on the specific requirements and techniques of using dual thickness equipment is essential for maximizing its potential.

Conclusion:

Dual thickness roll forming equipment has transformed the metal fabrication industry by offering enhanced flexibility, efficiency, and cost-effectiveness. The ability to produce profiles with varying thicknesses in a single run has opened up new possibilities for manufacturers in various sectors. By embracing this game-changing technology, metal fabricators can stay ahead of the competition and meet the evolving demands of their customers.