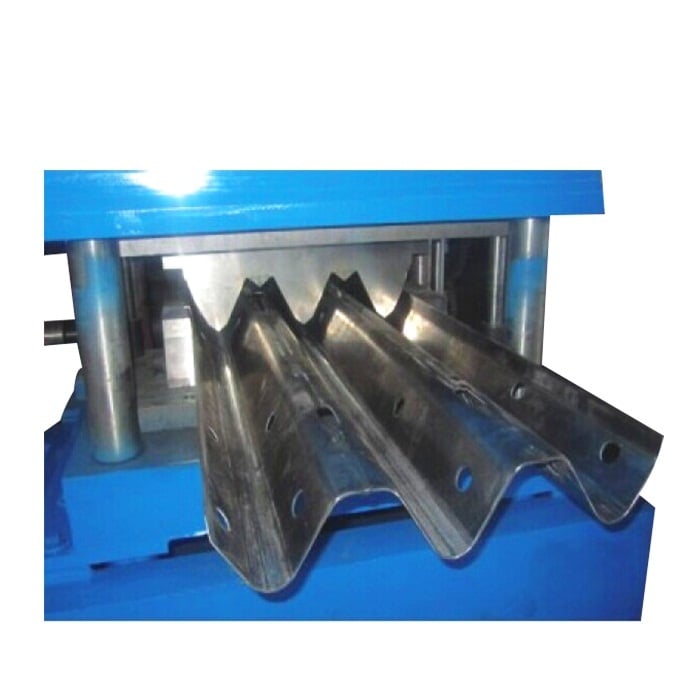

Highway guardrail roll forming machine

We provide free samples, you just need to cover the shipping cost. We sincerely look forward to cooperating with you for mutual benefit, and please contact us for any other questions.

Original Design Manufacturer

Manufacturing of metal cold forming equipment

One-stop sales and support services

Product Description

A highway guardrail roll forming machine is a specialized equipment used to produce highway guardrails. It is designed to efficiently and accurately roll form metal sheets into the desired shape and size of guardrails. The machine is capable of producing various types and profiles of guardrails, including W-beam, Thrie-beam, and other customized designs. It is widely used in the construction and maintenance of highways, expressways, and other road infrastructure projects.

Product Function

The primary function of a highway guardrail roll forming machine is to transform flat metal sheets into guardrails with the desired shape and dimensions. The machine uses a series of rollers and cutting tools to gradually shape the metal sheet according to the specific profile of the guardrail. It can also perform additional functions such as punching holes, embossing patterns, and adding reflective elements to the guardrails.

Product Application

Highway guardrail roll forming machines are essential in the production of guardrails for various applications. They are commonly used in highway construction projects, expressway upgrades, bridge constructions, and road safety improvement initiatives. The machine can produce guardrails of different lengths, widths, and thicknesses to meet the specific requirements of each project.

Product Quality Control

To ensure the high quality of the produced guardrails, the highway guardrail roll forming machine undergoes rigorous quality control measures. The machine is constructed using durable and reliable materials to ensure its stability and longevity. It is also equipped with precision components and advanced control systems to achieve accurate and consistent roll forming results. Additionally, regular maintenance and inspections are performed to ensure optimal performance and minimize downtime.

Product Stability

Safety is a top priority in the design and operation of a highway guardrail roll forming machine. The machine complies with all relevant safety standards and regulations to minimize risks to operators and other personnel. It incorporates safety features such as safety guards, interlocks, and emergency stop systems. Operator training and safety guidelines are provided to ensure safe and responsible machine operation.