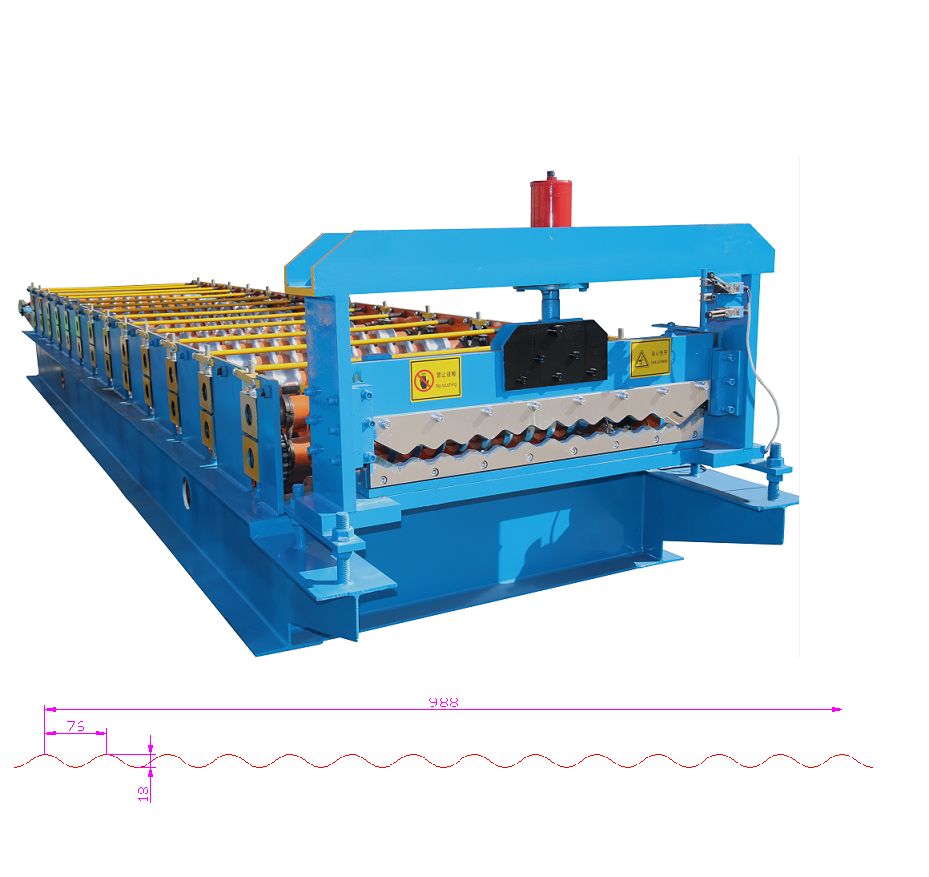

Roofing corrugated sheet roll forming machine

We provide free samples, you just need to cover the shipping cost. We sincerely look forward to cooperating with you for mutual benefit, and please contact us for any other questions.

Original Design Manufacturer

Manufacturing of metal cold forming equipment

One-stop sales and support services

Roofing Corrugated Sheet Roll Forming Machine: A Game Changer in Roofing Industry

Introduction:

The roofing industry has witnessed significant advancements in recent years, thanks to the introduction of innovative technologies and machinery. One such groundbreaking invention is the Roofing Corrugated Sheet Roll Forming Machine. This machine has revolutionized the way roofing sheets are manufactured, offering numerous benefits to both manufacturers and customers. In this article, we will explore the key features and advantages of this remarkable machine.

1. The Working Principle:

The Roofing Corrugated Sheet Roll Forming Machine operates on a simple yet highly efficient principle. It takes a continuous metal strip and passes it through a series of rollers that gradually shape the strip into a corrugated profile. The machine uses a combination of pressure and precision to create the desired shape, ensuring uniformity and accuracy in every sheet produced.

2. Versatility in Profile Design:

One of the significant advantages of the Roofing Corrugated Sheet Roll Forming Machine is its ability to produce a wide range of corrugated profiles. Whether you need a traditional sinusoidal profile or a custom design, this machine can handle it all. By adjusting the rollers and settings, manufacturers can create various profiles, catering to the diverse needs of different roofing projects.

3. High Production Efficiency:

Compared to traditional methods, the Roofing Corrugated Sheet Roll Forming Machine offers a remarkable improvement in production efficiency. It can produce roofing sheets at a much faster rate, reducing labor costs and increasing overall productivity. With its automated operation and minimal human intervention, this machine ensures a smooth and uninterrupted manufacturing process.

4. Superior Quality and Durability:

The precision and accuracy of the Roofing Corrugated Sheet Roll Forming Machine guarantee the production of high-quality roofing sheets. The machine eliminates the risk of human errors and inconsistencies, resulting in perfectly shaped and uniform sheets every time. Moreover, the use of durable materials in the machine's construction ensures its longevity and resistance to wear and tear.

5. Cost-effectiveness and Sustainability:

Investing in a Roofing Corrugated Sheet Roll Forming Machine can offer long-term cost savings for manufacturers. The machine's high production efficiency reduces material wastage and minimizes operational costs. Additionally, the use of recyclable materials in the production process makes the roofing sheets environmentally friendly, contributing to sustainable construction practices.

Conclusion:

The Roofing Corrugated Sheet Roll Forming Machine has undoubtedly transformed the roofing industry, bringing efficiency, versatility, and quality to the manufacturing process. Its ability to create various corrugated profiles, coupled with its high production efficiency and durability, makes it a game changer in the roofing sector. With the growing demand for innovative roofing solutions, investing in this machine can provide manufacturers with a competitive edge and customers with top-notch roofing products.