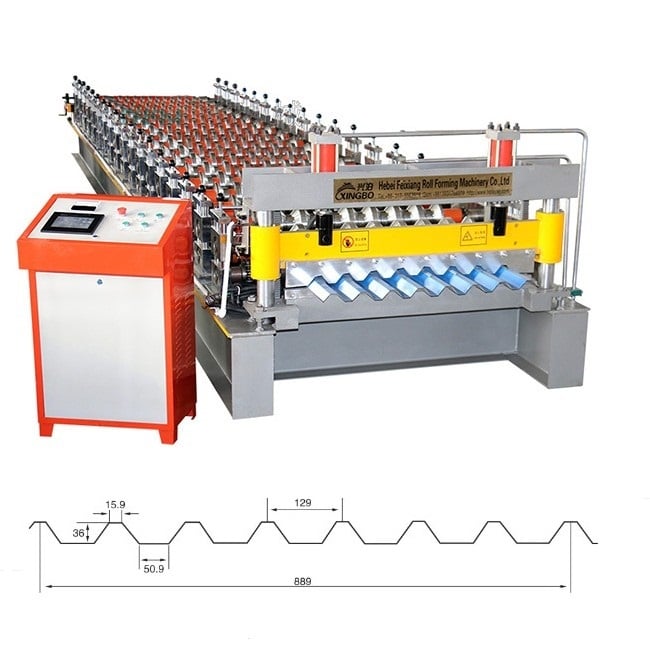

Trapezoidal roof sheet making machine

We provide free samples, you just need to cover the shipping cost. We sincerely look forward to cooperating with you for mutual benefit, and please contact us for any other questions.

Original Design Manufacturer

Manufacturing of metal cold forming equipment

One-stop sales and support services

Trapezoidal Roof Sheet Making Machine: Revolutionizing the Construction Industry

Introduction:

The construction industry is witnessing a significant technological advancement with the introduction of the Trapezoidal Roof Sheet Making Machine. This innovative machine has revolutionized the process of manufacturing trapezoidal roof sheets, offering numerous benefits to builders, contractors, and homeowners alike. In this article, we will explore the various features and advantages of this machine, highlighting its role in enhancing the efficiency and durability of roofing systems.

1. Understanding the Trapezoidal Roof Sheet Making Machine:

The Trapezoidal Roof Sheet Making Machine is a state-of-the-art equipment designed to automate the production of trapezoidal roof sheets. It consists of a series of rollers, cutters, and other mechanisms that transform raw materials, such as galvanized steel coils, into high-quality, standardized roof sheets. The machine operates on a computerized system, ensuring precision, speed, and consistency in the manufacturing process.

2. Enhanced Efficiency and Cost-Effectiveness:

One of the primary benefits of the Trapezoidal Roof Sheet Making Machine is its ability to significantly improve production efficiency. By automating the manufacturing process, the machine eliminates the need for manual labor, reducing the possibility of errors and increasing productivity. Moreover, the machine's high-speed operation enables faster production, allowing builders and contractors to complete roofing projects within shorter timeframes. This, in turn, leads to cost savings, as fewer labor hours are required.

3. Durability and Strength:

Trapezoidal roof sheets manufactured using this machine exhibit exceptional durability and strength. The machine's precise forming process ensures that the sheets have consistent dimensions, preventing any weak points or deformities. Additionally, the use of high-quality materials and advanced coating techniques enhances the sheets' resistance to corrosion, UV radiation, and other environmental factors. This durability translates into long-lasting roofing systems that require minimal maintenance and repairs over their lifespan.

4. Versatility and Customization:

The Trapezoidal Roof Sheet Making Machine offers builders and contractors a wide range of design options and customization possibilities. With adjustable parameters and settings, the machine can produce roof sheets of various lengths, widths, and thicknesses, catering to the specific requirements of each project. Additionally, the machine can incorporate different profiles and embossing patterns, allowing for unique aesthetics and architectural designs. This versatility eliminates the need for outsourcing and enables on-site customization, saving time and costs.

Conclusion:

The Trapezoidal Roof Sheet Making Machine is a game-changer in the construction industry, streamlining the production process and improving the quality and durability of trapezoidal roof sheets. Its automation capabilities, enhanced efficiency, and customization options make it an indispensable tool for builders and contractors. As the demand for durable and aesthetically pleasing roofing systems continues to rise, this machine proves to be an invaluable asset, ensuring the successful completion of projects while minimizing costs and maximizing customer satisfaction.