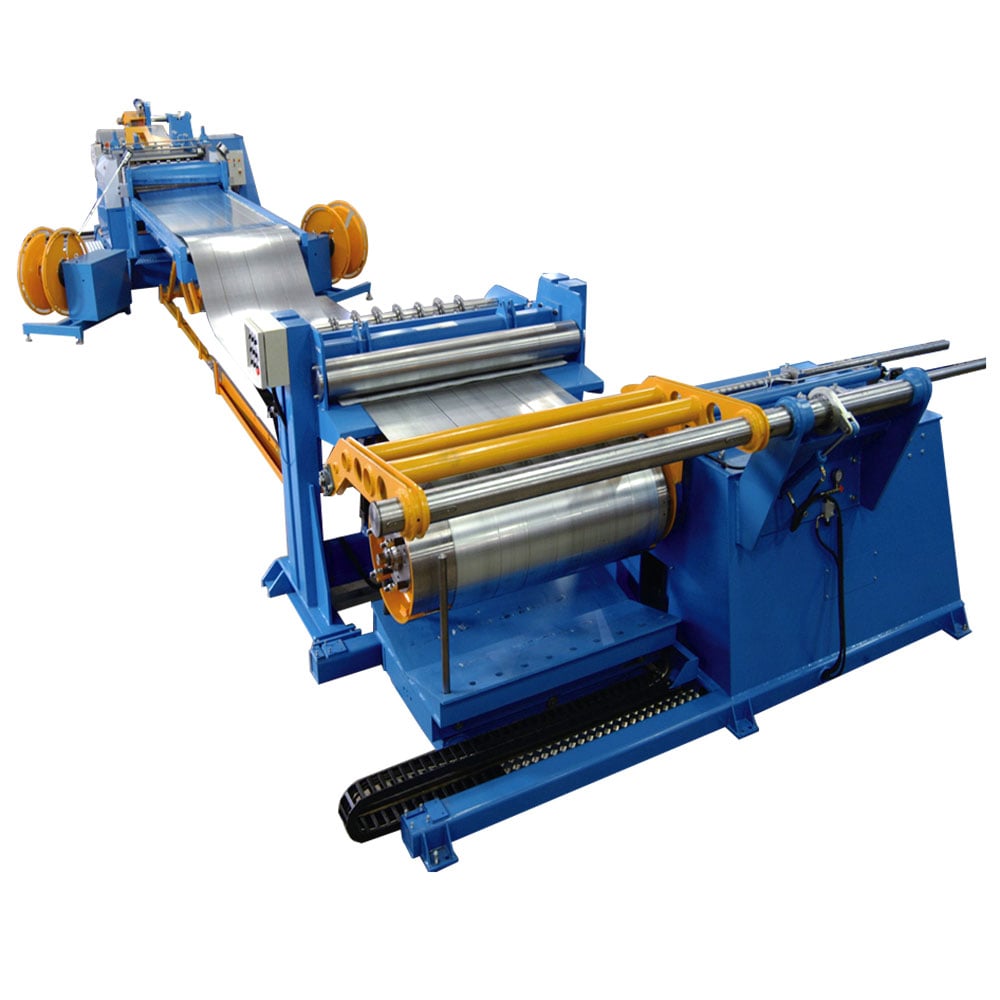

Steel coil slitting and cutting machine

We provide free samples, you just need to cover the shipping cost. We sincerely look forward to cooperating with you for mutual benefit, and please contact us for any other questions.

Original Design Manufacturer

Manufacturing of metal cold forming equipment

One-stop sales and support services

Product Description

A steel coil slitting and cutting machine is a specialized equipment designed for efficiently cutting and slitting steel coils. It is commonly used in industries such as metal processing, construction, and manufacturing. This machine is capable of handling various types and thicknesses of steel coils, providing precise and high-quality cuts and slits. It offers excellent versatility and productivity, making it an essential tool for steel processing operations.

The primary function of a steel coil slitting and cutting machine is to accurately and efficiently cut and slit steel coils into smaller, more manageable pieces. It is equipped with sharp blades and advanced cutting mechanisms that ensure precise and clean cuts, minimizing material waste. The machine can handle coils of different widths and thicknesses, and it offers customizable settings to meet specific cutting requirements. With its automated operation and high-speed performance, it significantly improves production efficiency and reduces manual labor.

Product Application

The steel coil slitting and cutting machine finds wide application in various industries that require steel processing. It is commonly used in metal fabrication and manufacturing plants, where steel coils are transformed into smaller components for further processing. It is also utilized in the construction industry for cutting and slitting steel coils used in the production of building materials. Additionally, the machine is suitable for steel service centers, steel distributors, and other businesses involved in steel processing operations.

Product Quality Control

To ensure the highest quality output, the steel coil slitting and cutting machine undergoes rigorous quality control measures. It is built with precision-engineered components and materials that meet industry standards, ensuring durability and reliability. Each machine is thoroughly tested before leaving the factory to guarantee its performance and accuracy. Additionally, regular maintenance and calibration are recommended to maintain optimal cutting precision and prolong the machine's lifespan.

Product Stability

The steel coil slitting and cutting machine is designed for stability and consistent performance. It features a robust and sturdy frame construction that minimizes vibrations during operation, resulting in precise and smooth cutting. The machine is equipped with advanced control systems that maintain accurate cutting parameters, ensuring stability throughout the cutting process. Its reliable and efficient design allows for continuous operation without compromising the quality of the output.

Product Safety

Safety is a top priority when operating the steel coil slitting and cutting machine. It is equipped with various safety features to protect operators and minimize the risk of accidents. These features include emergency stop buttons, safety guards, and sensors that detect abnormalities or obstructions during operation. The machine also conforms to relevant safety standards and regulations, providing operators with peace of mind while using the equipment.