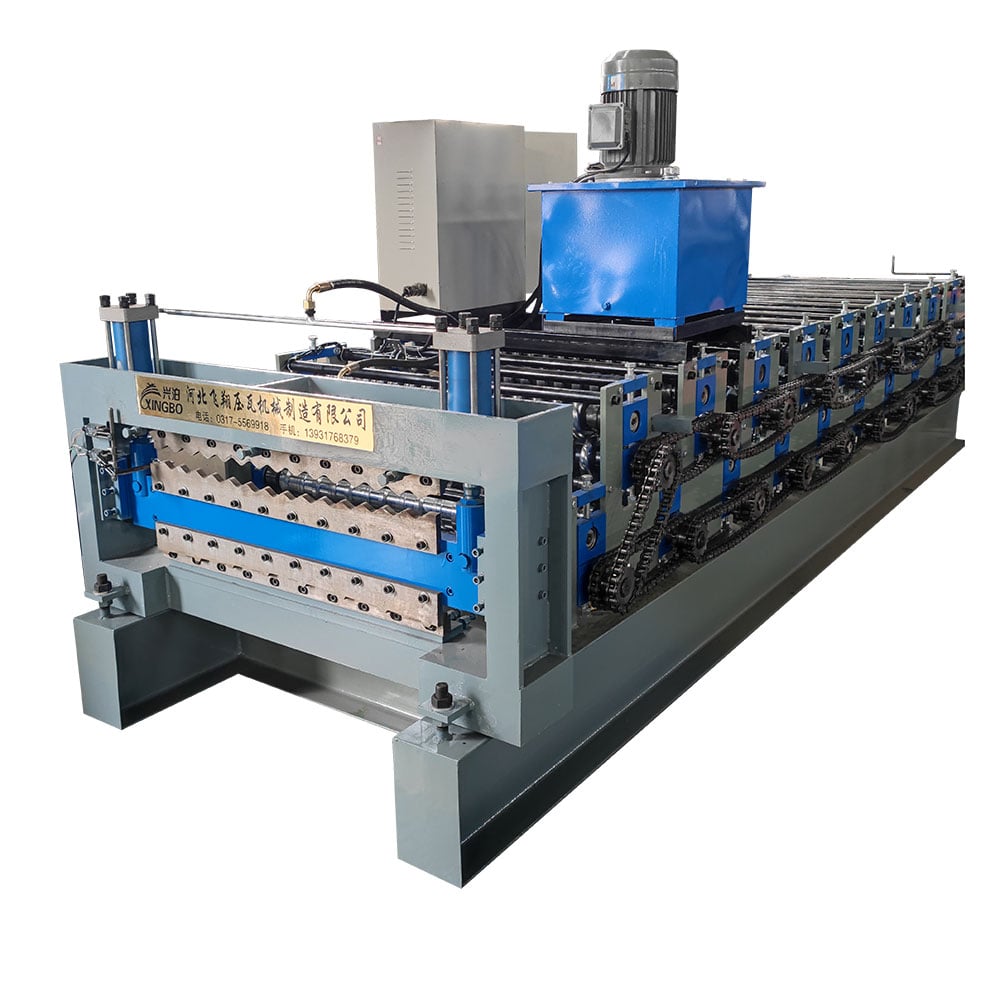

Double layer rack upright roll former

We provide free samples, you just need to cover the shipping cost. We sincerely look forward to cooperating with you for mutual benefit, and please contact us for any other questions.

Original Design Manufacturer

Manufacturing of metal cold forming equipment

One-stop sales and support services

Product Description:

The Double Layer Rack Upright Roll Former is a versatile and efficient machine designed specifically for the production of double layer rack uprights. With its advanced technology and sturdy construction, this roll former offers exceptional performance and precision in forming the uprights for various industrial and commercial applications.

1. Durable Construction

The Double Layer Rack Upright Roll Former is built with high-quality materials and components, ensuring its long-lasting durability and reliability. The robust frame and reinforced structure provide stability and support during the roll forming process, allowing the machine to withstand heavy-duty usage in demanding manufacturing environments.

2. Double Layer Capability

Featuring a unique design, this roll former has the ability to produce double layer rack uprights in a single pass. This means that the machine can efficiently form two layers of metal sheets simultaneously, significantly increasing productivity and reducing production time compared to traditional single-layer roll formers.

3. Precise Roll Forming

Equipped with advanced roll forming technology, the Double Layer Rack Upright Roll Former ensures precise and accurate shaping of the metal sheets. The adjustable roll forming stations allow for easy customization of the shape and dimensions of the uprights, making it suitable for various rack designs and specifications.

4. High-Speed Production

Thanks to its efficient design and powerful motor, this roll former can achieve high production speeds without compromising on quality. The automatic feeding system and synchronized roll forming process enable continuous and rapid production, making it an ideal choice for manufacturers with high-volume production requirements.

5. User-Friendly Controls

The Double Layer Rack Upright Roll Former is equipped with user-friendly controls and an intuitive interface, allowing operators to easily set and adjust the machine parameters. The digital display provides real-time information and feedback, ensuring accurate and precise control over the roll forming process.

6. Versatile Applications

With its capability to produce double layer rack uprights, this roll former is suitable for a wide range of applications. It can be used in the manufacturing of storage racks, shelving systems, warehouse equipment, and more. The flexibility of the machine allows for the production of various rack sizes and configurations to meet diverse customer needs.

7. Efficient Material Utilization

The Double Layer Rack Upright Roll Former optimizes material utilization, minimizing waste and reducing production costs. By forming two layers of metal sheets simultaneously, the machine maximizes the usage of raw materials, ensuring efficient production and minimizing scrap material.

8. Low Maintenance

Designed for ease of use and maintenance, this roll former requires minimal upkeep. The durable components and well-engineered design minimize the risk of breakdowns and reduce the need for frequent repairs. Regular maintenance routines are simple and can be easily performed, ensuring minimal downtime and maximizing productivity.

9. Safe Operation

Safety is a top priority in the design of the Double Layer Rack Upright Roll Former. The machine is equipped with safety features such as emergency stop buttons, protective covers, and sensors to prevent accidents and ensure operator safety. Compliance with international safety standards guarantees a secure and worry-free operation.

10. Cost-Effective Investment

Investing in the Double Layer Rack Upright Roll Former offers a cost-effective solution for manufacturers in need of high-quality rack uprights. Its efficient production capabilities, durable construction, and low maintenance requirements contribute to a significant return on investment over the machine's lifespan. With increased productivity and reduced production costs, manufacturers can achieve higher profitability and gain a competitive edge in the market.